Cover Story

Testing the IQ of Your IAQ

Efficiency versus effectiveness: Examining true air cleaner performance.

Efficient and effective filtration is one of the foundational pillars of any well-designed building HVAC system. With regard to air filters and cleaners, efficiency is a term that refers to the ability of a collecting medium to capture contaminants from the airstream that pass through it. The effectiveness of an air cleaner refers to its ability to reduce particulate concentrations in a space. The U.S. Environmental Protection Agency (EPA) tells us, “It should be noted that expected removal efficiencies for air-cleaning devices are not the same as the effectiveness of the unit in actual use. Efficiency only measures the percent removal of contaminants in the air that flows through the air-cleaning device. Effectiveness in use depends on how much of the interior air actually goes through the unit in a given time period”1.

If space contaminants in the air do not pass through the air filter that is tasked with their removal, the effectiveness (actual contaminants removed) may be less than expected regardless of the filter’s rated efficiency. Simply put, a filter described as very efficient may not be all that effective in actual use.

Rating Filter Efficiency

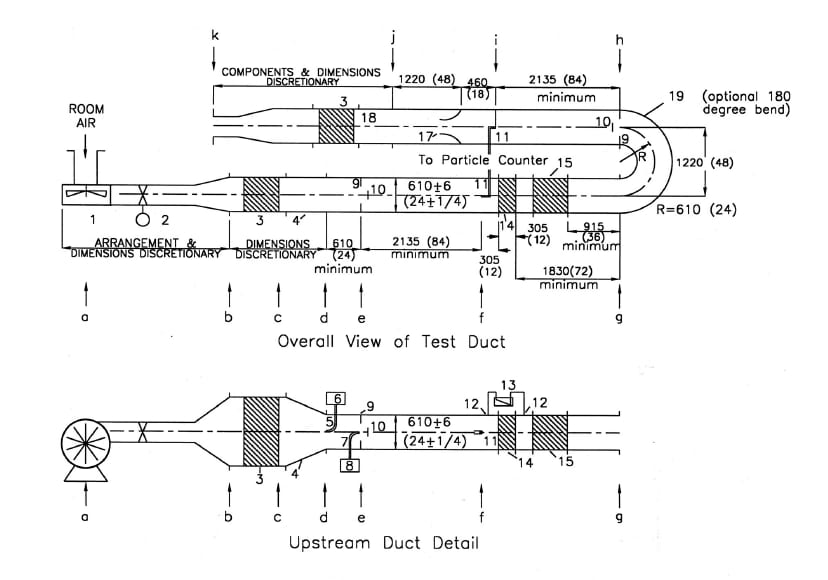

ASHRAE Standard 52.2, “Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size,” has established a test procedure for evaluating the performance of air-cleaning devices (filters) as a function of particle size. This standard describes a method of laboratory testing to measure the performance of general ventilation air-cleaning devices using a test apparatus like the one shown in Figure 1.

FIGURE 1: Schematic of Test Duct - ASHRAE Std 52.1-2017.

Summarizing the test procedure, a stable, dry, and uniform challenge aerosol (particulate) ranging in size from 0.30-10 micrometers (μm) is introduced downstream of an injection fan that is positioned immediately upstream of the air filter being evaluated. This propels test particles into the inlet of the filter at air velocities up to several hundred feet per minute (fpm). A particle counter then measures and counts the particles both upstream and downstream of the filter for the efficiency determinations. ASHRAE cautions the user must be aware the tests are made under laboratory conditions using synthetic dust for loading. AHRAE also specifically states: “Since the contaminant used for loading is not typical of natural atmospheric dust, its effect on the filter may not be the same as an equal amount of atmospheric dust. The value of the loading test is for rating and, to some extent, ranking filters. The performance values obtained in accordance with this standard cannot be used by themselves to predict air cleanliness of a specific ventilated space or the service life of an installed filter.”

While the ASHRAE rating methodology may be a useful measure of an air cleaner’s tested efficiency, it may not be indicative of its effectiveness in true application. Most real-world contaminants are not synthetic, and the vast majority of particles in the indoor air we breathe are smaller (much smaller) than the minimum 0.30 μm size used for these rating procedures. Typical room air velocities may range more on the order of 20-50 fpm, and many HVAC systems do not have return air injection fans. Also, the contaminants of concern in the air may be located considerable distances from the filter itself and are not force-fed at a high velocity and close range into the inlet of the device tasked with removing them. In a recent trade magazine interview, Tom Justice, former head of research and development for Purolator’s HVAC division, vice president of operations, and later COO (retired) at Flanders Corp., stated, “I think the biggest challenge is to develop a more suitable test to replicate performance in real-life situations. So, basically, we need laboratory results to come much closer to real-life performance for filters. People who know filtration and performance in-situ testing see standards as not necessarily representative of filters' actual performance. In other words, it performs this way in a laboratory but not necessarily in real life.”2

The National Air Filtration Association (NAFA) Guide to Air Filtration, sixth edition 2021, reminds us that while we are inclined to think of air filtration as an irreversible action where a dust particle is captured once and then stays captured, this is not true of dry media filters, especially those in the high-efficiency range. A particle may be captured by a fiber only to become restrained in the airstream and then either be captured by another fiber downstream or pass through the filter altogether. When considering commercial HVAC applications, multiple filters may be installed for side access and slid into the filter housing on formed metal tracks. Formed metal tracks may offer no sealing mechanism at the filter-to-track interface or between filters installed side by side. Often, standard-size filters do not completely fill these tracks. This lack of sealing may result in significant leakage via air bypass, which can degrade overall filtration efficiency3. All of the aforementioned real-world dynamics will certainly have an impact on any air cleaner’s true effectiveness.

Applying Current Guidance

Scientific study has concluded that small particles and pathogens, including SARS-CoV-2 and other viruses, may be of insufficient mass to be controlled by bulk airflow and can remain suspended in the indoor air for days or even weeks. It’s reported that significant fractions of the fine and ultra-fine particles in the air may not be effectively transported to or removed by conventional air filters and that even ultralow penetration and HEPA filters are only effective on the particles and pathogens that can reach the filter, not those that remain suspended in the space4. ASHRAE stated in a November 2020 ASHRAE Journal article that research has not provided evidence of the transmission of the SARS-CoV-2 virus through HVAC systems, although, within a space, air motion caused by HVAC system components as well as fans can be a factor5. On March 23, the U.S. Centers for Disease Control Preventions (CDC) updated its COVID-19 ventilation FAQ’s titled: “Can COVID-19 be Transmitted Through HVAC Ventilation Systems?” They stated that the risk of spreading SARS-CoV-2 through ventilation systems is not currently clear and that while airflows within a particular space may help spread disease among people in that space, there is no definitive evidence to date that viable virus has been transmitted through an HVAC system to result in disease transmission to people in other spaces served by the same system.

This most up-to-date information could be telling us that traditional HVAC strategies might have a reduced impact on cleaning the indoor environment because the small pollutants of concern are not being effectively moved out of the space and into the HVAC system to be exhausted, filtered, or additionally treated. HVAC system air-cleaning strategies should certainly be capable of more than just waiting for virus and contaminant-laden air to “get-to-it” for treatment. Easily understood is a simple concept that if the pollutants in the space are removed, they are no longer a concern to its inhabitants. This would be a major accomplishment for all building air-cleaning systems; therefore, something different than what we are now doing may warrant consideration. Understanding these dynamics is key in helping us to properly design building HVAC systems that can contribute to the well-being and productivity of occupants breathing the indoor air.

Improving IAQ

Because ventilation and filtration comprise the backbone of any well-designed building HVAC system, implementing additional measures to ensure they are more efficient and effective makes sense if we are to achieve maximum results. Designs that enhance ventilation rate effectiveness, help maintain proper indoor relative humidity, and actively treat to clean the indoor space (where the contaminants of concern originate and may remain) could prove prudent. Any technology that improves the efficacy of traditional ventilation and filtration warrants thoughtful consideration. Listed below are a few potential solutions that can be applied at the space level to treat the interior space itself and help garner improved results.

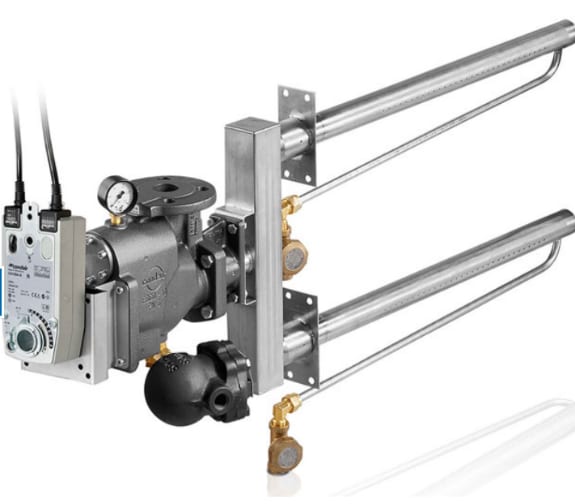

Humidification studies have shown that keeping a building's breathing zone between the ranges of 40%-60% relative humidity (RH) can influence occupants' well-being as well as help limit the spread of airborne viruses. If the air is too dry, respiratory droplets expelled by infected individuals can quickly evaporate and shrink. These tiny, desiccated particles can be more easily suspended in the air, where they may travel by air currents in the space to spread infection among occupants. Research from the National Institute of Health (NIH), Princeton, and Harvard shows the infectivity of viruses in the air and on surfaces can be reduced when the proper relative humidity is maintained in this range. Data also shows when people within the built environment are exposed to proper indoor relative humidity, their “human mechanisms” for physiological defense are improved.

FIGURE 2: A duct-mounted steam humidifier grid.

Stand-alone and portable air cleaners can be selected, sized, installed, and operated without modifying existing mechanical ventilation systems, which may not have been engineered to handle large enough airflows or high levels of filtration. They can help limit the spread of viruses and other contaminants that occur via long-range airborne transmission by working (in the space) to capture potentially infectious particles within a high-efficiency filter while changing the air at a targeted rate of four times (or more) per hour. This has the effect of improving ventilation effectiveness in the space. If the stand-alone air cleaner uses HEPA filters, the device may be rated at an efficiency to remove 99.97% of airborne particles with an aerodynamic size of approximately 0.2 microns and even more particles of both smaller and larger size. This is true only when these particles can get to the filter to be captured.

FIGURE 3: A stand-alone portable HEPA air scrubber.

Upper air ultraviolet germicidal irradiation (UVGI) devices use fixtures located within the occupied environment, designed and installed to irradiate only air in the upper region of the space. Efficacy of this technology relies on fixture placement and the adequacy of air currents in bringing contaminated air into the upper UV zone. In buildings with continuous occupancy or with immunocompromised populations, such as health care environments, upper air UV-C systems may help control transmission of airborne pathogens at their source. Studies have shown that, in combination with appropriate room ventilation measures, it can be effective at helping to reduce the spread of certain airborne infectious diseases, such as tuberculous. One caveat to these systems is that the CDC has stated they can only be used to supplement other air-cleaning systems.

FIGURE 4: An upper room mounted UVGI lights.

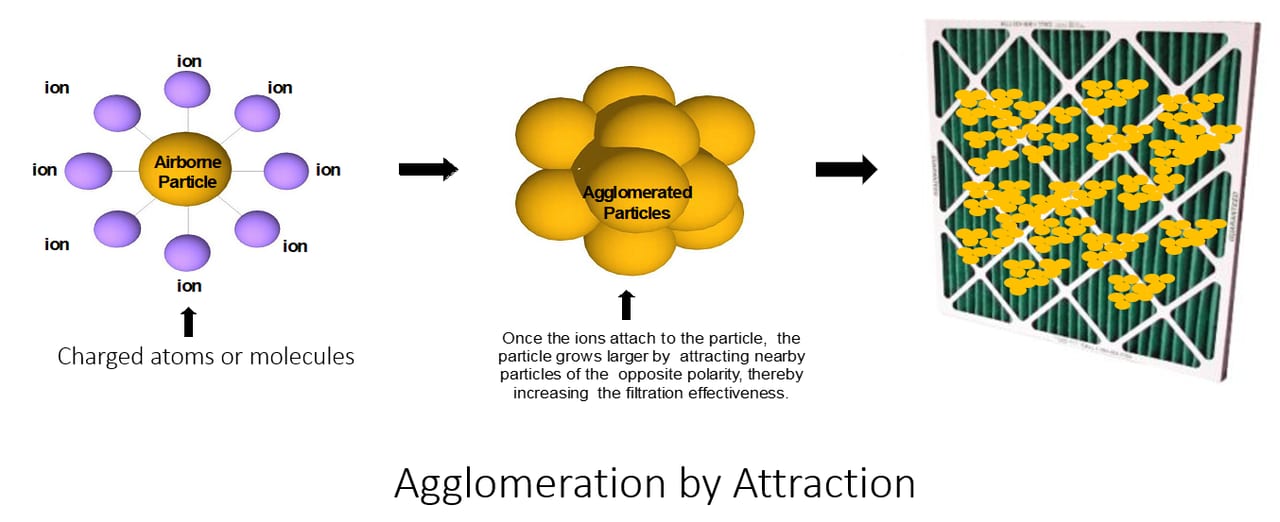

Needlepoint bipolar ionization (NPBI) is a patented air-cleaning technology that can be installed within the HVAC system but works on the contaminants and pollutants in the space, where the issues of concern originate and may remain. While not a filter itself, NPBI can supplement traditional ventilation and filtration by influencing the removal of small airborne particulate (viruses, pathogens, and other contaminants) from the environment based on the principle of electrostatic attraction and agglomeration.

Ions, like those already abundant in cleaner outdoor air, are generated from within the HVAC system. When released and distributed throughout the building, they mix with room air and attach (electrostatically) to airborne particles. As these charged particles are increasingly attracted and joined to one another, their size and weight is increased to the point where they (now being larger) can be more easily influenced by HVAC system air movement. Particles may now be effectively removed from the space and exhausted, filtered, or treated. Air filters become more effective at removing these larger particles from the air, while any other internally mounted HVAC system air purification device (including filters) can encounter the pollutants they have been tasked with cleaning, those which before may have remained in the space untouched.

Recent air ionization testing and analysis by the Built Environment Research Group, Department of Civil, Architectural, and Environmental Engineering at the Illinois Institute of Technology8, has presented some compelling results. The clean air delivery rate (CADR) of a tested air cleaner was improved by 44% for 0.9-1.0 µm size particles (smoke), 19% for 0.5-3.0 µm size particles (dust), and 53% for 5.0-10.0 µm size particles (pollen). Based on these results, scientists estimated that between 20%-50% of the measured CADR during normal operation may be attributable to the ionization process. With the basic understanding that everything in the air we breathe is a particle, and that the removal of these particles is fundamental in improving IAQ, this important research provides additional insight into how air may be more effectively cleaned.

FIGURE 5: NPBI electrostatic agglomeration of small particles.

Conclusion

Filtration and ventilation are two key components in creating truly productive environments for individuals occupying buildings of all types. The field of IAQ is ripe for advancements that can make upgrades to either of these more effective and affordable. Add to any of the innovative solutions described above the assurance that the HVAC system is being properly serviced and maintained over its operational lifetime, and you will have taken major steps toward making sure we are both efficiently and effectively cleaning the air we breathe.

References

- Introduction to Indoor Air Quality, A Self-Paced Learning Module-United States Environmental Protection Agency, Office of Air and Radiation, EPA/400/3-91/002, July 1999.

- International Filtration News, Insights, Issues & Innovations: Filtration Standards-Friend of Foe? Issue 5/2021

- American Conference of Governmental Industrial Hygienists (ACGIH), Bioaerosols Committee, Engineering Controls for Bioaerosols in Non-Industrial/Non-Healthcare Settings, 2021.

- Mark H. Ereth MD, Donald H. Hess MSME, Abigail Driscoll BS, Mark Hernandez PhD, Frank Frank Stamatatos BEE, Particle Control Reduces Fine and Ultrafine Particles Greater than HEPA Filtration in Live Operating Rooms and Kills Biologic Warfare Surrogate, American Journal of Infection Control, 2019.

- ETF Chair: Limited Virus Knowledge is Key Challenge, ASHRAE Journal, November 2020.

- ANSI/ASHRAE Standard 185.1-2020 Method of Testing UV-C Lights for Use in Air-Handling Units or Air Ducts to Inactivate Airborn Microorganisms.

- John McCarthy, SC.D., C.I.H., Member ASHRAE, Kevin Coghlan, Preparing HVAC Systems Before Reoccupying A Building, ASHRAE Journal, January 2021.

- Portable Air Cleaner Test Report, Built Environment Research Group, Department of Civil, Architectural, and Environmental Engineering, Illinois Institute of Technology, August 2021.

David Schurk, DES, CEM, LEED AP, CDSM, CWEP, SFP, CIAQM, CHC

David Schurk is the director of health care and applied engineering markets for Global Plasma Solutions in Charlotte, North Carolina. He is a licensed designer of engineering systems and has more than 40-years of experience in the design and analysis of HVAC systems for a variety of market sectors with a special focus on aerospace and health care facilities. He has authored various technical articles for major industry trade journals and magazines, along with being a featured presenter at regional and national industry events. Contact him at 920-530-7677.

Video courtesy of UV Resources