Development and Operation of a District Energy System in Schenectady, New York

The Proctors Performing Arts Center is the only theatre in the country that provides district energy to itself and its neighborhood.

SCROLL

District energy (DE) systems supply heating and cooling from a central energy source to multiple customers (commercial, residential, and industrial). The economics of DE is based on a series of local conditions that require significant study, such as the potential customer base, new planned developments, fuel usage and cost, and the age of existing energy systems. One action that planning organizations can take is to commission a community energy study that analyzes the local market both to understand what areas of the city would have the appropriate demand characteristics to justify a DE system. The DE system should start with the development of building clusters most feasible for interconnection. It is well known that consolidation of various buildings into a combined DE system allows for the reduction of the peak combined load demand and the individual building energy cost.

Many different types of organizations, such as municipal governments, utilities, owners, and managers of buildings and private developers, could be involved in the development of the DE. Each of these organizations has its own interests, perceptions, and, in many cases, misperceptions of DE. A major challenge exists, therefore, for the proponent or "champion" of a DE to gain the acceptance and support from this diverse set of organizations for a proposed project.

Gaining support for a new DE system requires the effective promotion of the benefits of the proposed system. The proponent must clearly and credibly communicate the ways in which a DE system can contribute to meeting each group's self-interest. However, many do not have experience in marketing and promotion and have difficulty seeing themselves in the role of promoters. Implementing DE requires local champions and developers have patience and a willingness to stick to long-term plans.

The successful experience with community-scale projects indicate that one of the feasible options is to create a district piping loop connecting the customers. The loop will allow aggregation of customers into a district system and increase the efficiency of the energy source. The district loop will gradually be expanded into a community-scale system. The project should be located in the downtown areas. This allows aggregation of energy consumption of multiple customers with minimum piping cost and creation of the first stages or islands of the DE system. The islands are gradually expanded into a larger system by adding new customers. The current paper demonstrates such development of a DE in the city of Schenectady.

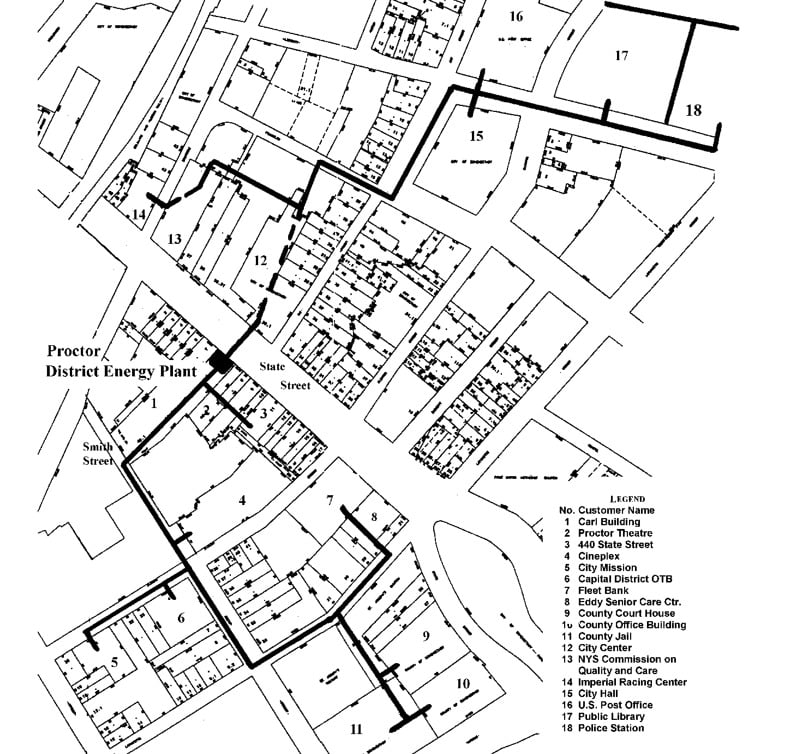

Figure 1

The Proctors Complex in Schenectady, New York.

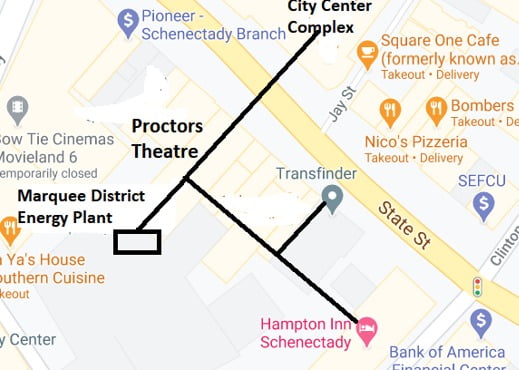

Figure 2

The Proctors district in downtown Schenectady.

Photo courtesy of Google

Background

In 2000, Philip Morris assumed the responsibility of the CEO of the Proctors Performing Art Center in Schenectady, New York (Figures 1-2). Having extensive experience with district heating in the City of Jamestown, New York1, he commissioned Joseph Technology Corporation (JTC), which specializes in DE, to develop a similar system for the central downtown area of Schenectady emanating from Proctor’s Theater. The New York State Energy Research and Development Authority (NYSERDA) shared the initial cost of the project. In 2004-2005, PPAC administrators started extensive reconstruction of the complex consisting of four buildings in downtown Schenectady. The stage house at Proctors was greatly enlarged, and the former Carl Company was converted to box office, café, and administrative spaces. All existing buildings were heated with boilers and cooled with various separate cooling systems. All of the equipment was old and needed replacement. It was decided to construct a new DE facility and begin a new business named MARQUEE POWER (MP). Proctors also decided to operate the DE plant and be responsible for the energy distribution piping system.

Figure 3

The Proctors' original district energy piping diagram.

Figure 4

An overall view of the Proctors' district energy plant.

Photo by Richard Lovrich

System Description

From the beginning, in addition to the Proctors Theatre Complex, the interconnection of several buildings in the vicinity of the 400 block of State Street was planned. The original service area developed by JTC2 included 18 customers (Figure 3). Today, the MP DE plant supplies thermal energy for heating and cooling of buildings with an area close to 1 million square feet of downtown Schenectady, including the PPAC, Hampton Inn Hotel, Transfinder Corp., Parker Inn, a dozen or so large and small customers located within the City Center Block across State Street, and a snow melting system for most of the block containing PPAC’s facilities (Figure 3). Proctors is the only theatre in the country that provides DE to itself and its neighborhood3.

Originally, the MP DE plant was comprised of two natural gas-fired, 250-HP steam boilers; two 500-ton absorption chillers; and one 250-ton screw electric chiller. The boiler steam system was designed for steam usage by the absorption chillers (purchased from an abandoned site at minimum cost). The hot water was generated in steam to hot water heat exchangers (Figures 4-5).

The distribution system consisted of a four-pipe, modern, pre-insulated underground system for hot and chilled water. During the reconstruction of State Street, at the recommendation of JTC, four district pipes were installed under the street in order to supply customers on the other site of the street. JTC also proposed the installation of a snow melting system under the sidewalk of the State Street (Figure 6).

Recent upgrades have increased the plant's heating capacity with two 250-HP and one 110-HP hot water boilers. The absorption chillers were replaced with two 500-ton electric centrifugal chillers. The DE plant has the necessary backup capacity and additional space for expansion. The plant heating system has been converted from steam to hot water. The internal heating systems of the customers are separated from the DE system by heat exchangers within their facility. Each customer is also equipped with a Btu meter in order to track their energy consumption. The customers are billed for usage in accordance with actual metered consumption and established rate structures for heating and cooling.

With the economy of scale (diversity factor of combined customers) and modern efficient equipment, a DE system is typically more efficient than individual customers generating energy of their own, providing a lower cost option to neighboring businesses in the community. As buildings are being renovated in downtown Schenectady, the system also helps economic development and revitalization of the downtown.

With built-in redundancy, MP can handle more customers when they are ready for interconnection. The DE plant was purpose-built with the foresight of expansion. In addition to having the equipment and the capability to serve existing customers, the plant has the capacity to serve more, even with the current equipment. The community appreciates Proctors as a good, clean, quiet neighbor, providing reliable service to ensure the customers are comfortable and confident in their work environments.

Figure 5

The Marquee district energy plant in Schenectady, New York.

Photo courtesy of ME Engineering

Figure 6

Proctors' current district energy piping diagram.

Summary of Benefits of the DE System

- The operational experience demonstrates that the DE system provides about 30% energy savings versus on-site self-generation of thermal energy to customers;

- Customers are freed from both maintenance and operation of on-site energy facilities;

- Besides providing cost-effective and reliable energy for connected buildings, customers avoid capital investments for expensive boilers, chillers, and other on-site energy equipment;

- Frees up valuable building space. No boilers, chillers, cooling towers, and other auxiliary energy equipment are located in the building;

- Not having to manage and maintain energy systems allows customers to focus on their particular business rather than providing their own energy services;

- The DE system operates year-round and without service interruptions, providing exceptional reliability;

- The district cooling system reduces peak electric power demand in the buildings, helping businesses avoid expensive peak demand charges that are typical with on-site cooling systems;

- There is no release of any pollutants from building energy systems, including greenhouse gases (GHG). This reduces the area’s carbon footprint by more than 500 metric tons of CO₂ each year;

- The system stimulates economic development and downtown revitalization; and

- The PPAC enjoys energy stability as the keeps the energy rates have remained stable.

References

- Oliker, I. 20 Years Later, the Jamestown Story. The District Energy Magazine, March 2005.

- Oliker, I. Feasibility of the New District Energy System in Downtown Schenectady, New York. Proctors, Joseph Technology Corporation, 2003.

- Eck, Michael. How Proctors Heats Up Downtown Schenectady. Proctors Collaborative, Mar.29, 2019.

Elihu Jerabek

Elihu Jerabek is a consultant to Marquee Power. His role is focused on energy data-mining, concerning both the district energy products and the electric and gas consumed. He is retired from General Electric, where he worked for 36 years in electrochemistry at the corporate research and development center, followed by seven years at GE Microgen, a unit formed to market residential fuel cell systems from Plug Power. In retirement, he has consulted in battery technologies and designed his residential solar energy installation.

Richard Tortorici III

Richard Tortorici III is the Proctor’s director of facilities, including the district energy plant. He has close to 20 years of engineering, architectural, and managerial experience with different facilities, including Watervliet Arsenal and Benet Weapons Laboratory. He can be reached at 518-266-4565 and richard.w.tortorici2@gmail.com.

Philip Morris

Philip Morris is the CEO of Proctors, the Performing Arts Center of the Capital District, located in Schenectady, New York, and TheRep, the region's only professional producing theater. Over the last 15 years, under his direction, Proctors has raised and invested nearly $50 million to expand its stage, add a flexible-use 430-seat theater (the GE), expand public spaces, create conference facilities, and build a district energy plant that supplies neighboring buildings and businesses with utilities that heat and cool as well as melt the show under the sidewalks around Proctors' block, reducing users' energy cost and substantially reducing the carbon footprint of the buildings involved. He can be reached at 518-346-3884 and pmorris@proctors.org.

Dr. I. Oliker

Dr. I. Oliker, president of Joseph Technology Corporation, has been involved in district energy development, design, and construction in the U.S., China, South Korea, Russia, Kazakhstan, Tadzhikistan, and Kirgizstan for more than 25 years. He received his master’s degree and Ph.D. in district heating from the Moscow Engineering Institute. He is a licensed professional engineer in 10 U.S. states and the past president of the International District Energy Association. He was involved in the development of more than 25 district energy systems in the U.S. and overseas. He is the author of 175 technical papers, eight books, and 15 patents. He can be reached at 201-573-0529; jtcincorp@optonline.net, or at http://oliker.net.

Photo courtesy of Pixabay