AER Direct Drive Configurable Condenser Fan – Greenheck

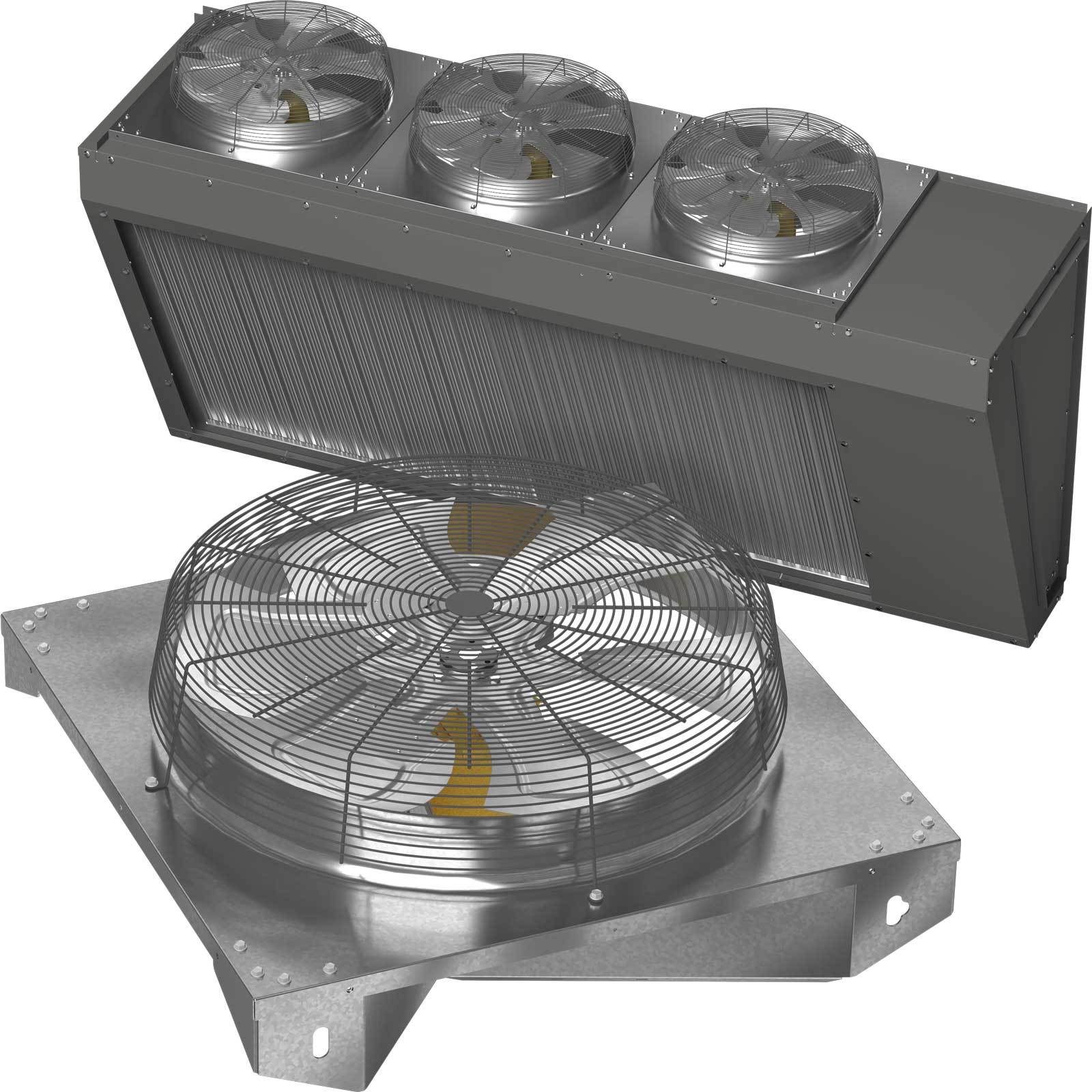

SCHOFIELD, Wis. — Greenheck’s new AER direct drive configurable condenser fan can help regulate temperature and provide proper ventilation, even in the most demanding applications, where elevated water and temperature protection is required. Available in four sizes, ranging from 20-36, the AER condenser fan offers performance up to 29,800 cfm and external static pressure up to 2.80 in. wg.

Model AER features galvanized steel construction and can be specified in multiple mounting configurations with fabricated steel or cast-aluminum propellers. Motor options include alternating current (AC) or electronically commutated motors (ECMs) that can be specified with up to IP55 and 60c severe-duty motor protection ratings. Air Movement and Control Association (AMCA)-certified for Sound and Air Performance and UL/cUL 705 listed, the AER condenser fan is ideal for clean air applications, including tempered air systems, dedicated outdoor air systems (DOAS), data centers, data mining, and other mission critical applications.

Greenheck

www.greenheck.com

GOLD RX Air-Handling Unit – Swegon

AJAX, Ontario, Canada — Swegon’s GOLD RX is a complete air-handling unit (AHU) with rotary heat exchanger, direct-driven supply air, extract air fans, and supply air and extract air filters.

The unit features temperature efficiency via a heat exchanger that is up to 85% efficient, airflow up to 16,300 cfm, a variable-speed control for rotary heat exchanger, heat and cooling energy recovery, and more.

Optimized fan sizes give greater freedom to choose exactly the right size of AHU and fan variants to suit the needs of the installation. This also gives even greater possibilities to optimize the energy efficiency of the current project

A rotary heat exchanger consists of an aluminum wheel with numerous small air passages. Energy is transferred between the supply air and extract air or vice versa when the wheel rotates. This is among the most energy-efficient heat recovery methods with a temperature efficiency that always exceeds 80%. Thanks to a patented design with turbulent flow in the air passages, RECOnomic attains a uniquely high degree of energy efficiency.

Swegon

https://swegonnorthamerica.com/products/air-handlingbackup/gold-na-rx

VF1A Doesa Variable Frequency Drives – IDEC Corp.

SUNNYVALE, Calif. — IDEC Corp. now offers a new line of VF1A Doesa variable frequency drives (VFDs), providing versatile control and efficient operation of electrical motors for a wide range of applications.

VFDs are used to control the speed and torque of AC motors so users can optimize system performance by running equipment at just the speed required to meet the demand of the load. Furthermore, VFDs are configurable to accelerate and decelerate to commanded speed smoothly, reducing the wear and tear on associated mechanical components. Among the greatest of VFD benefits is the energy savings realized by running a motor at any speed below maximum, so long as the equipment needs are met.

IDEC VF1A Doesa VFDs are suitable for speed control of variable and constant torque applications, ranging from fans and pumps to specialized equipment. The VFD is capable of driving an induction motor (IM) or a permanent magnet synchronous motor (PMSM). IMs can be driven in open loop or closed loop, while PMSMs can be driven in open loop only.

The product family features a compact form factor in a UL open-type construction with nickel- and tin-plated bus bars and conformal coatings for corrosion protection. The VFD is designed for a long operating life and provides a maintenance alarm signal.

Electrical input is nominally rated as three-phase, low-voltage AC 400V (with an allowable input voltage range of 380-480 VAC), and the VFDs come in 14 models with a capacity range of up to 139A. Each VFD is quadruple-rated for varying duties — normal or heavy overload and mild 40°C or high 50°C temperatures — so users can minimize the number of models needed to handle a wide range of applications.

IDEC Corp.

http://www.us.idec.com/c/VF1A_Series

Digital Pressure Temperature Sensor – DunAn Microstaq

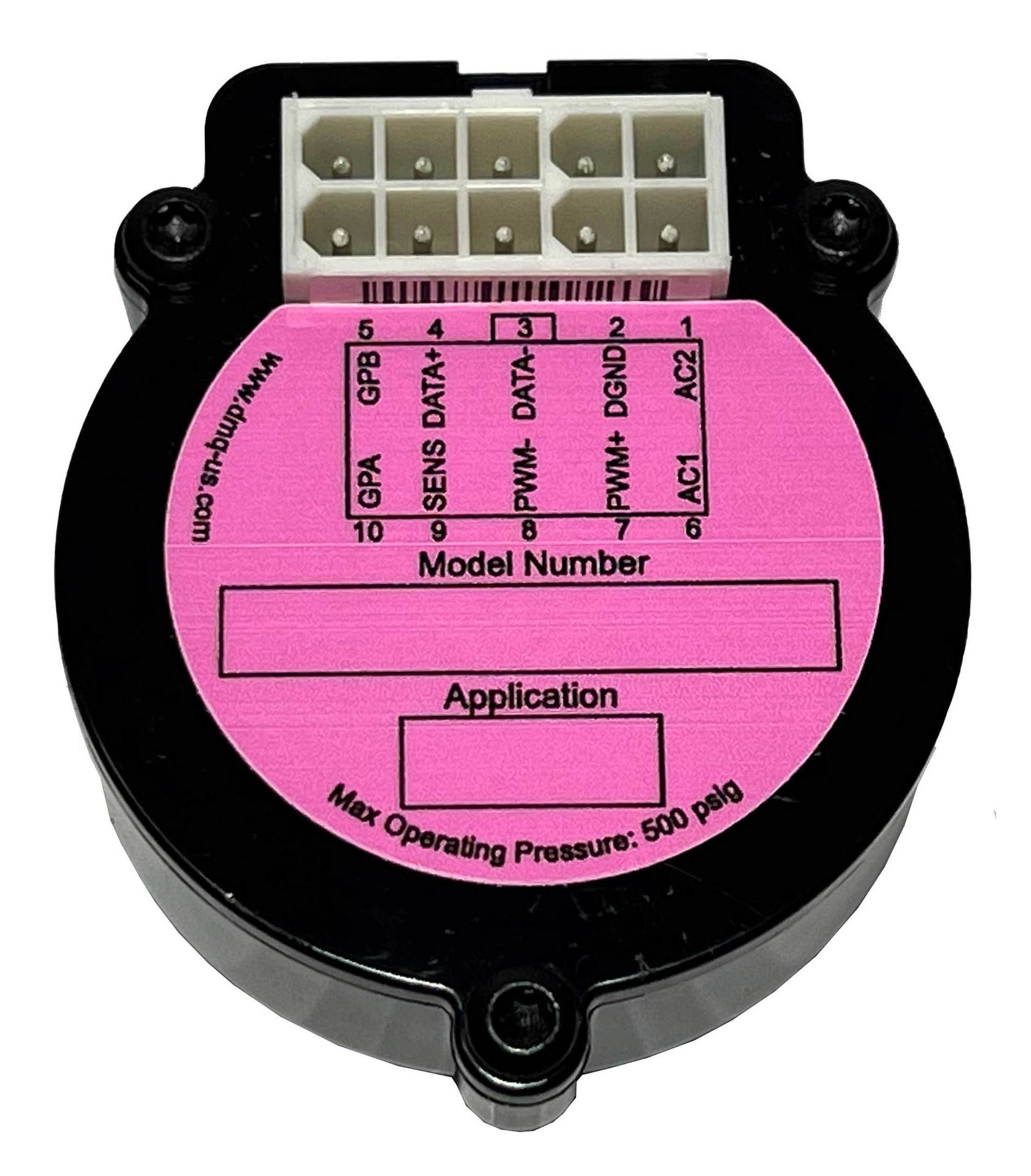

AUSTIN, Texas — DunAn Microstaq Inc. (DMQ), a MEMS technology company, now offers a Digital Pressure Temperature Sensor (DPTS) to measure subcooling for HVACR applications.

The DPTS is a self-contained device that measures pressure and temperature and calculates subcooling based on refrigerant type. It is compatible with all ASHRAE safety groups A1, A2, and A2L refrigerants. The latest generation DPTS can read maximum pressure between 500-700 psi.

The DPTS is available as a superheat sensor as well. In a HVACR system, two DPTS sensors can be used to measure superheat and subcooling. Superheat measurements monitor the efficiency of the HVACR system and can be used as a safety sensor to protect the compressor from liquid flooding. Subcooling measurements monitor the refrigerant charge level and control the high-pressure flow control valve to maintain the condenser mass flow rate for optimum performance (DMQ Patent No. 10,648,719).

The end user communicates with DPTS devices via the RS485 communication bus using the Modbus RTU communication protocol. The DPTS is installed on a ¼-inch SAE 45-degree flare male fitting for pressure measurements, and a temperature sensor from the DPTS wiring harness is installed at the exit of the evaporator for superheat measurement or at the exit of the condenser for subcooling measurement. The end user may utilize both superheat and subcooling readings as input to trigger a programmable output to electrical equipment, such as valves, actuators, or compressor contactors, via solid-state relays.

DunAn Microstaq Inc.

https://www.dmq-us.com/product/digital-pressure-temperature-sensor-dpts

RTS-30 and RTS-03 Series Automatic Transfer Switches with Manual Bypass/Isolation – Russelectric

HINGHAM, Mass. — Russelectric, a Siemens business, highlights its range of automatic transfer switches with bypass/isolation, which allows the transfer switch portion to be isolated and de-energized for maintenance, testing, or repair. The Russelectric RTS-30 Series and Russelectric RTS-03 Series transfer switches provide all the functions of a Russelectric automatic transfer switch plus the ability to bypass power from a live source to load in the event the transfer switch is disabled.

Russelectric RTS-30 Series automatic transfer switches with manual bypass/isolation are a complete line of 480-VAC, 30-cycle, and three-cycle UL tested switches. They have been fully tested, listed, and labeled for 30-cycle and three-cycle closing and withstand ratings under UL-1008. Full draw-out construction allows safe and easy removal of the transfer switch, eliminating the need to make any electrical or mechanical disconnections. Russelectric offers both fail-safe and maintenance bypass switch designs.

Built rugged for long life, minimum maintenance, and trouble-free service, the RTS-30 Series features contact assemblies designed to handle the rigors of 30-cycle closing and withstand performance and offer exceptional arc- and track-resistance. The main contact pad material is designed to prevent overheating, and stationary contact pad material prevents welding during high fault current conditions.

Also offered are Russelectric RTS-03 Series transfer switches with manual bypass/isolation, which feature high three-cycle closing and withstand ratings for 480 VAC or less of any switches available today. All Russelectric RTS-03 Series automatic transfer switches have been fully tested for three-cycle closing and withstand ratings under UL-1008. When coordinated with current limiting fuses, Russelectric RTS-03 Series transfer switches have UL listed closing and withstand ratings of 200,000 amperes at 480 VAC.

Russelectric

https://usa.siemens.com/bypassswitches

µRack Compressor Rack Controller – Carel

BRUGINE, Italy — Carel’s µRack is a complete solution for compact and efficient compressor rack that offers a complete set of functions for controlling small condensing units and compressor racks, ensuring reliability, efficiency, and ease of use.

The unit exploits Carel’s extensive experience in refrigeration controllers and offers all the benefits of the latest-generation connectivity. With Bluetooth and NFC included as standard, µRack offers the opportunity to interface the unit with a smartphone via the Carel Applica app, making configuration easy and intuitive. During the session, details will be provided on the generic functions available to users for versatile operation of the controller. All of the options, such as floating condensing control, fan modulation, and compressor speed control, are designed to obtain maximum energy savings.

Another distinctive feature of the entire range of rack controllers is the built-in BMS port, which allows a connection to Carel supervisory systems for remote monitoring and performance optimization throughout the entire system life cycle. Finally, the RED optimize cloud platform offers the possibility to log the operating data acquired, simplifying maintenance, diagnosing any malfunctions, and measuring energy savings.

Carel

www.carel.com

Enhanced ProTools Mobile App – Weil-McLain

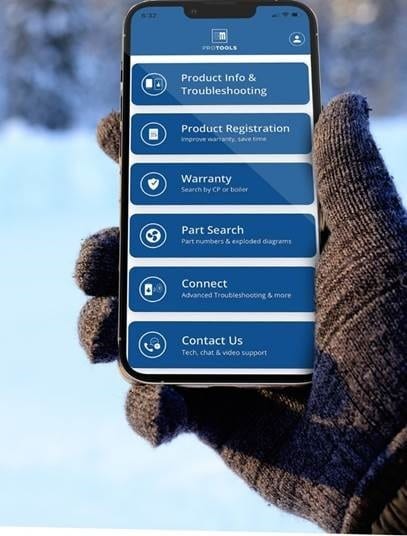

BURR RIDGE, Ill. — Just in time for heating season, Weil-McLain® has updated its ProTools™ App with enhanced features to provide contractors and service technicians with the support they need to streamline customer visits and provide clients with a premium experience. Available for iOS and Android devices, the app now allows heating professionals to work virtually with Weil-McLain’s Tech Support team to problem-solve issues as they occur on the job site.

“Our goal is to continuously optimize this platform by adding additional features that make service technicians’ and installing contractors’ jobs easier – especially during the busy heating season period,” said David DeVries, director of product management, Weil-McLain. “The new Site-Call video assistance opens new opportunities for service technicians to receive instant support from our tech support team.”

Service technicians who run into complications while on the job can contact Weil-McLain tech support for site-call video and receive immediate real-time assistance. After requesting support, technicians can simply accept a call from tech support on their smartphones and share live videos of the issues they are experiencing on the job site. Tech support will then highlight the issue on the service technician’s screen and propose corrective action to solve it.

“This new feature provides heating professionals with immediate access to our support team and also allows them the opportunity to learn new methods for troubleshooting, maintenance, and boiler setup,” said DeVries. “As we prepare for what could be another colder than normal winter, we want to ensure service technicians have all the digital tools and knowledge they need to help expedite customer visits while providing homeowners a best-in-class service experience.”

Weil-McLain

www.weil-mclain.com