feature

FA MRI Room Detection – Designing Aspirating Smoke Detection

Safety isn’t an option; it’s a requirement. The right consultants can help engineers not only be aware of their obligations but meet them.

Most facilities have some number of critical and sensitive pieces of equipment. Server rooms, battery storage rooms, laboratories, stages, or other complex areas require a thoughtful approach to fire protection. The use of aspirating smoke detection can be a lifesaver under certain conditions. A prime example is magnetic resonance imaging (MRI), which is typically found in hospitals and other health care occupancies. MRI uses strong magnets to image the human body. The rooms housing the scanners are usually magnetically shielded, and the presence of magnetic materials is prohibited.

This article is intended to explain aspirating smoke detection as a viable alternative to typical spot smoke detectors that have magnetic components and cannot be used and provide some initial tips on how to represent it in an engineering design to be issued for solicitation of bids. This approach is focused on MRI rooms as an example but is broadly applicable wherever aspirating smoke detection is desirable.

Determining If Protection Is Required

The applicable building code is always the first place to look when determining what the minimum level of protection is for each space in a facility. A building, or section of a building, is classified based on its occupancy. This classification defines its prescriptive protection. References made in this article are to the unamended building code. Be sure to verify whether a respective jurisdictional authority has made amendments to these requirements. Health care requirements are a common recipient of amendments.

An MRI room is a medical use space in which occupants are incapable of self-preservation. As such, it would conservatively be considered an ambulatory health care occupancy by National Fire Protection Association (NFPA) 101 and an Institutional Group I-2 Condition 2 occupancy by the International Building Code (IBC).

When the jurisdiction adopts NFPA 101, Chapters 20 and 21 detail the requirements for new and existing ambulatory health care occupancies, respectively. For this exercise, let's focus on new construction but know the approach to finding requirements in existing buildings is the same in Chapter 21. Section 20.3.4 establishes what detection, alarm, and communications systems are required throughout these occupancies. Section 2.3.4.2 only requires that manual alarm initiation be used in addition to the common automatic detection required in section 9.6.2.

Where the IBC is adopted instead of NFPA 101, Chapter 4 contains special detailed requirements based on use and occupancy. Section 407 touches on Group I-2 occupancies specifically. Section 407.8 largely requires corridors and spaces open to corridors have automatic fire detection. Chapter 9 dictates fire protection systems requirements, and section 907 focuses on fire alarm and detection systems. Section 907.2.6.2 for Group I-2 occupancies restates the requirements of section 407.

In both codes, automatic fire detection in MRI rooms is not an explicit requirement. That said, the presence of fire alarm or suppression systems can relax restrictions, like maximum travel distances and maximum care suite areas. Facility stakeholders may separately require that high-value equipment, like MRI machines, be protected beyond what the code mandates.

The design may necessitate the installation of a fire alarm or suppression system, even if the code does not.

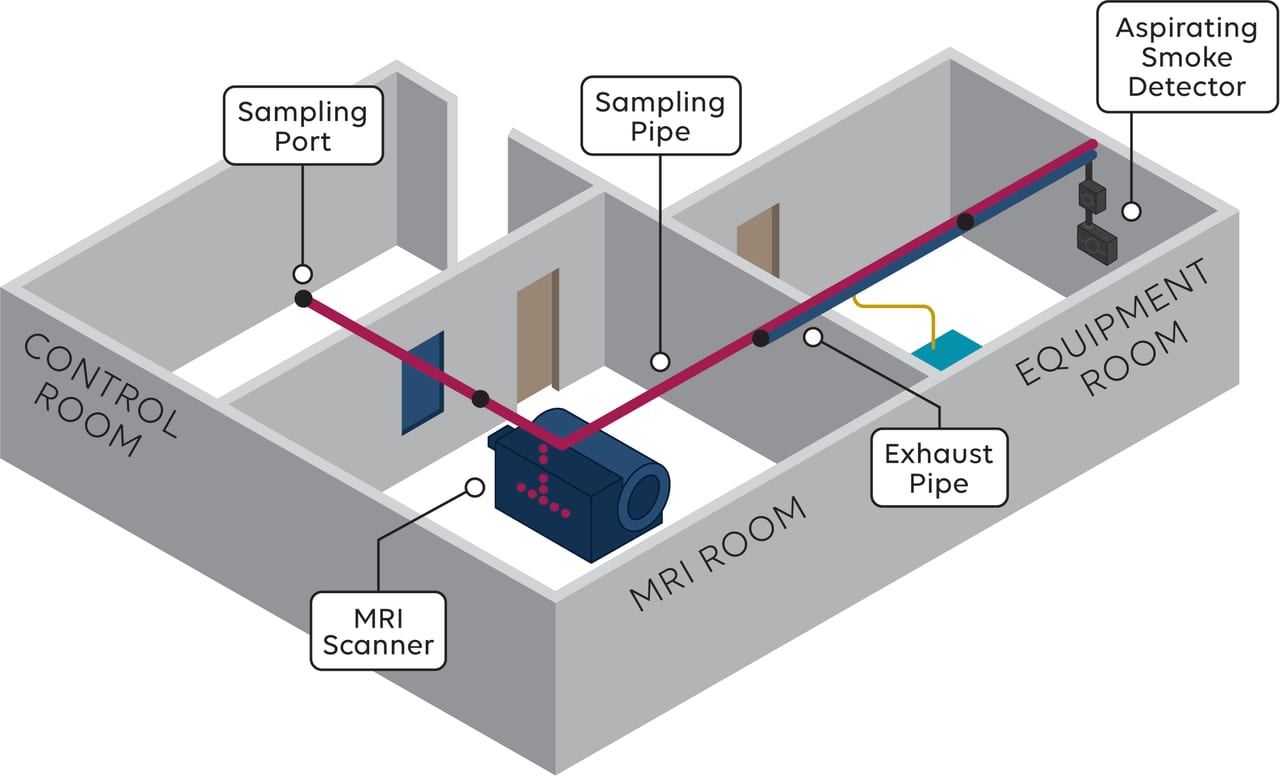

FIGURE 1: A sample arrangement of aspirating smoke detection in an MRI room.

Image courtesy of HGA

Smoke Detection for MRI Rooms

Fire detection and suppression buys the critical time needed to investigate an alarm and initiate an appropriate response to prevent injury, property damage, or business disruption. If the design of the space calls for smoke detection, either as a means of monitoring for fire to notify occupants or to activate a fire suppression system, standard spot-type detectors generally cannot be used because of the magnetic components used in their construction. Manufacturers can be consulted to request information on non-ferromagnetic alternatives, but the most common alternative is aspirating smoke detection.

An aspirating single detector is connected to a system of sampling pipes. It pulls air from the protected area through the pipes to the detector for analysis. The smoke detector then sends an alarm signal, just as any other detector would. The main difference is that aspirating smoke detection can identify smoke particulate at a lower concentration than most other methods, allowing for earlier notification or response. While more expensive than many other forms of fire detection on a per-unit basis, these systems do offer advantages.

The benefits of aspirating smoke detection are uniquely beneficial in MRI rooms. The smoke detector itself can be located outside the space it monitors. By specifying polyvinyl chloride (PVC) or copper sampling pipes, the design excludes magnetic fire detection components in the space.

Wall-mounted smoke detectors outside the MRI room can be in a corridor, equipment room, control room, or in any other available space. A keynote on the design documents in the rooms to be monitored should indicate they are “monitored by aspirating smoke detection.”

In addition to standard language about the component, the specifications provided should clearly state that nonmagnetic sampling pipes are to be used. To avoid compromising the integrity of the MRI room shielding, all penetrations must pass through a wave guide. They should also dictate that exhausted air should be returned to the MRI scanner room. While there may be circumstances where this is not necessary, it’s a valuable habit to adopt. Airflow faults in rooms monitoring pressure can and should be avoided in this way.

With these elements, the installation contractor providing the system should have enough data to further develop the design and coordinate system mounting, sample pipe routing, and sampling port locations.

Additional Considerations

Aspirating smoke detection can provide area smoke detection but can also be used to consolidate other functions into a single component. If mechanical system vents in/around the MRI room are monitored by fire detection, they can utilize the same smoke detector. If requested by the client, sampling ports can be installed inside the MRI scanner to monitor the equipment wiring and cabinets. If gas detection is needed in the space, most manufacturers produce additional components that allow the aspirating smoke detector to identify the presence of selected gases in addition to smoke particulates.

It’s worth keeping in mind that a single aspirating smoke detector can protect multiple rooms. Because of this, when possible, it would be worthwhile to locate these spaces adjacent to one another. This would maximize the efficiency of the device, but the costs of these detectors are not high enough to significantly influence the flow of operations within the health care facility when compared to other factors.

Available Products

Aspirating smoke detection provides a significantly different approach when compared to other fire detection options. It has established a niche significant enough to encourage many systems manufacturers to produce their own product. While the VESDA system produced by Xtralis is the Kleenex of the market, enjoying near synonymous name recognition, engineers will find that proprietary detectors are typically available for all fire alarm systems, regardless of the control panel manufacturer.

But, the existence of multiple manufacturers does not imply they are all equal. The market for aspirating smoke detection is just coming out of its infancy. Because of this, the products available are rapidly evolving. System component costs, sizes, reliability, functionality, and availability are changing quickly to the degree that exploring options on every project is good practice. At any moment, a single manufacturer’s product may have leapt past the competition in one or more ways that make it the objectively best option. At other times, the playing field may have been leveled, and, with all manufacturers at relative parity, it may be best to adopt the model that best integrates with the rest of the fire alarm system.

While it’s unlikely that any one of the options available on the market is incapable of meeting individual performance criteria, it's worth considering a nonproprietary designer who is not associated with any specific manufacturer. Their independence can help engineers evaluate the pros and cons of all the choices available. They will help to ensure the final system provides the functionality needed with the least complexity for facilities maintenance and operations teams. When working in health care, the costs of disruption can be significantly higher than elsewhere, but it is worth considering in any facility.

Conclusion

Fire protection, as a practice, has grown immensely from simple coordination of sprinklers and smoke detectors. As new hazards and environments have been identified, so, too, has the industry of fire alarm system manufacturers risen to these new challenges. Aspirating smoke detection is a critical piece of technology in MRI rooms and other unique circumstances. During design, it’s important to consult with a subject matter expert, like a fire protection manufacturer, installer, or licensed fire protection engineer, to understand the options available.

Safety isn’t an option; it’s a requirement. The right consultants can help engineers not only be aware of their obligations but meet them.

Eric Roeder, P.E., PSP

Eric Roeder directs life safety and fire protection services across HGA’s national offices and market sectors. With 10 years of experience specializing in fire, life safety, and security systems for new and existing buildings and campuses in multiple markets, Roeder brings together diverse teams to work collaboratively. He has worked with jurisdictions to assess performance-based design approaches and address code permitting and approval processes.

Lead photo courtesy of HGA. ©Halkin/Mason Architectural Photography LLC