Feature

SCROLL

The Emergence of Grid-Sized Battery Energy Storage System Services

Energy storage systems will be critical components in future electrical distribution systems.

One of the most important technologies that substantially influence the quality of our lives and is vastly underappreciated is the ubiquitous battery. Whether it's the lead-acid batteries that start your car, the lithium-ion batteries that power your phone, or the nickel-cadmium batteries in your smoke detectors; batteries provide the energy necessary to operate the modern world.

As part of the long-term greenhouse gas reduction plan, all fossil fuel burning cars and heating equipment will be replaced with cars and heating equipment powered by electric versions. Though most power generation stations today are powered by fossil fuels, it is a shared vision to utilize more renewable wind and solar power generation in the future. Converting fossil fuel burning cars and heating equipment to electricity will require a substantial capital investment in upgrading the existing electrical distribution system. Grid-sized battery energy storage systems (BESSs) will be critical components in future electrical distribution systems.

This article will discuss the services grid-sized BESSs provide, battery performance characteristics, different battery technologies available and their performance characteristics, BESS technical standards, BESSs layout, and modular versus BESS arrangements.

Grid-Sized BESS Services

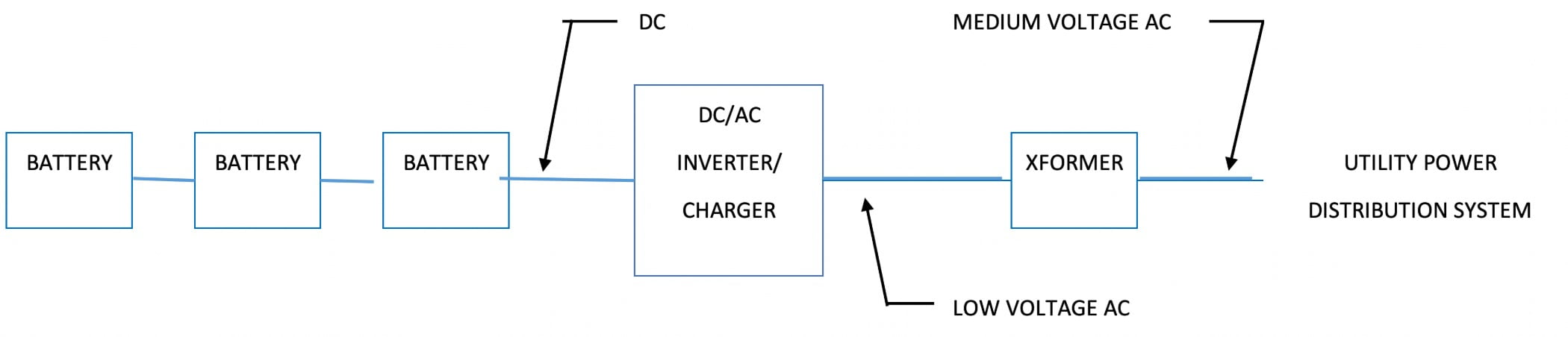

A grid-sized BESS is defined as having a power capacity of 1 MW or larger. Recently, it was announced a 100-MW BESS is to be built in Texas, which will be the single highest power capacity BESS in the U.S. The grid-sized BESS has batteries, DC/AC inverters/chargers, and transformers (see Figure 2) that are connected to the utility grid. There are a number of applications where BESSs provide benefits to power grids. The primary applications where they are utilized today include the following.

Frequency Regulation — Utility power systems have defined power generation and distribution capabilities. Due to their large sizes, power generation stations sometimes cannot respond as quickly as power distribution system demand fluctuations. The imbalance between the power supply and demand can lead to a dip or rise in grid frequency beyond its specified limits. Grid-sized BESSs can provide instantaneous responses to power distribution demand fluctuations, resulting in power distribution frequencies staying within specified limits. Typically, grid-sized BESSs utilized for frequency regulation have high power capacity (kW) and low energy capacity (kWh) since the battery storage system is only used for short durations (seconds to an hour).

Renewable Energy Management — Wind turbine systems provide highly variable power generation based upon available wind and solar photovoltaic systems, which provide highly variable power generation based upon the time of day and passing cloud cover. The availability of time-of-day renewable energy power generation may not coincide with the utility grid’s high demand periods, resulting in renewable energy curtailment. Grid-sized BESSs can provide two advantages to renewable energy systems:

Capacity Firming — With the variable renewable energy being stored in batteries, a stable battery power distribution can be provided to the utility grid; and

High Demand Distribution — The renewable energy battery system can supply power to the utility distribution system during peak power demand periods.

FIGURE 1. An example of a battery energy storage system facility.

Images courtesy of PCI SKANSKA Inc.

FIGURE 2: The grid-sized battery energy storage system has batteries, a DC/AC inverter/charger, and a transformer connected to the utility grid.

In 2016, there were 19 renewable energy systems in the U.S. that were co-located with battery storage systems. The number of co-located system increased to 53 in 2019 and is expected to double by 2023. The BESS power capacity (kW) will be predicated upon the renewable energy system’s anticipated power generation, and the energy capacity (kWh) will be for longer durations (hours).

Firm Capacity — Utility power distribution typically has peak demands during specific times of day and/or year. These peak demands are met by high-cost peak-shaving generators that operate for short durations. Grid-sized battery systems have become cost-competitive with peak-shaving generators and provide another option to utility companies. The BESS power capacity (kW) will be predicated upon the needed peak-shaving load requirement, and the energy capacity (kWh) will be for longer durations (hours).

Arbitrage — Arbitrage is defined as charging grid-sized battery storage systems with purchased power during off-peak, lower-cost time periods and selling the power during high-cost peak time periods. The BESS power capacity (KW) will be predicated upon the level of capital investment desired, and the energy capacity (kWh) will be for longer durations (hours).

Capital Investment Deferral — As utility power distribution demand increases, the existing power distribution may not have the capacity to meet the entire power distribution demand. One way to defer the capital investment of increasing the utility power distribution demand capacity is to install grid-sized BESSs at key locations that provide peak-shaving power distribution, which is designed to minimize the chance the utility power distribution system becomes overloaded. The BESS power capacity (kW) will be predicated upon the needed peak-shaving load requirement, and the energy capacity (kWh) will be for longer durations (hours).

Black Start — In the event of a power distribution failure, a grid-sized BESS can provide start-up restoration power to the power generation stations.

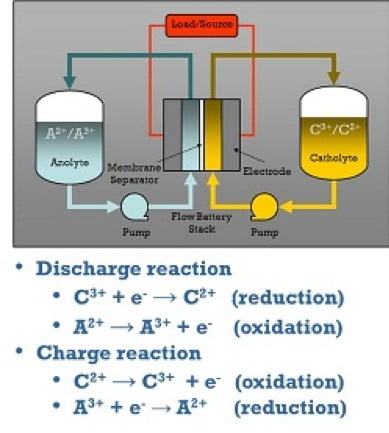

FIGURE 3: Flow batteries have one (or more) chemical component(s) that is dissolved in a liquid solution.

Battery Performance Characteristics

There are many different battery technologies, and each has unique performance characteristics. In grid-sized BESSs, some of the specific battery performance characteristics evaluated include energy density, specific power, charge/discharge efficiency, cycle durability, and self-discharge. A description of each performance characteristic is as follows:

Energy Density is the amount of energy a battery can store per unit of weight. Typically, the energy density is measured in watt-hours per kilogram (W-h/kg). The larger a battery’s energy density is, the fewer batteries are needed to provide a specific energy capacity.

Specific Power is the rate of energy discharge a battery can provide per unit of weight. Typically, the specific power is measured in watts per kilogram (W/kg). The higher a battery’s specific power is, the fewer batteries are needed to provide a specific power rate.

Charge/Discharge Efficiency is how efficient a battery charges and discharges. Heat dissipation is one form of battery charging/discharging inefficiency. For grid-sized BESSs, the batteries need to have a high charge/discharge efficiency.

Cycle Duration is the small amount of degradation most electrochemical-type batteries experience a after each charge/discharge cycle. Your car battery is a good example of a battery that “dies” after many charge/discharge cycles. For grid-sized BESSs, the batteries need to maintain energy density and specific power after many charge/discharge cycles. There are many variables that affect cycle duration, including depth of charge, specific battery configuration, and environmental conditions. The cycle duration values provided in Table 1 are based upon an average.

Self-Discharge is where the battery loses a portion of its charge without being discharged. This phenomenon is caused by chemical reactions within the battery and measured in charge dissipation percentage per month. For grid-sized BESSs, the batteries need to have low self-discharge.

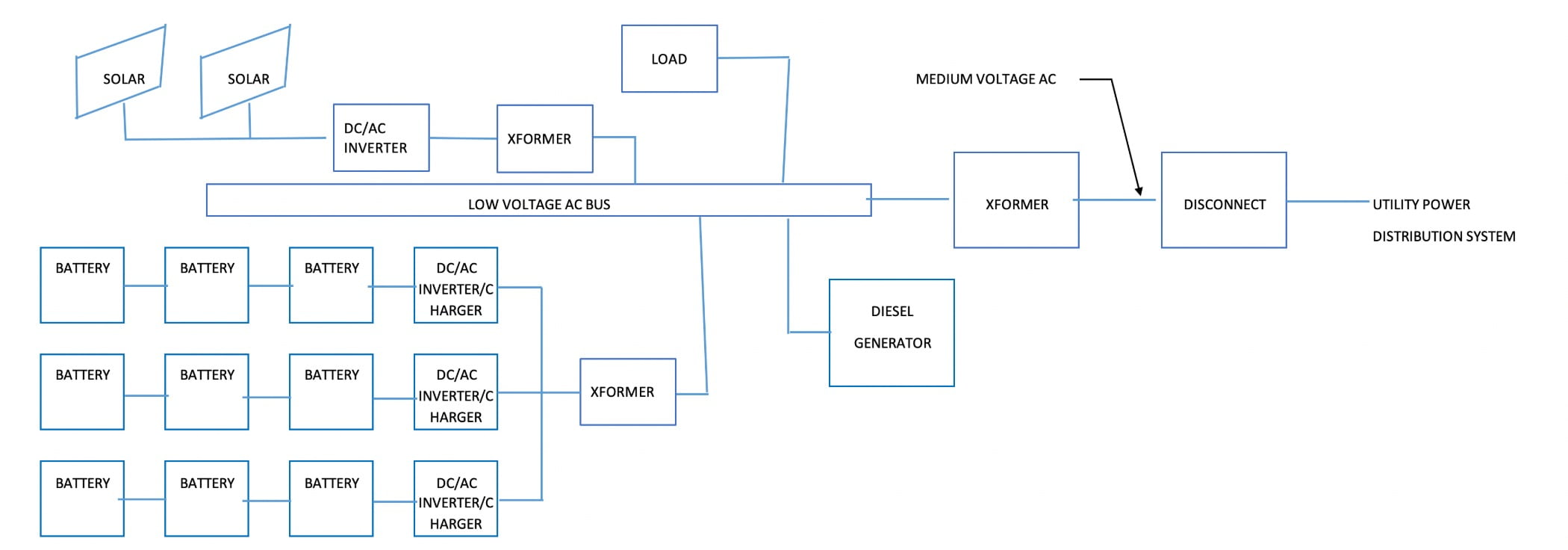

FIGURE 4: A grid-sized battery energy storage system with a solar system and diesel generator.

Different Battery Technologies and Performance Characteristics

There are many different battery technologies available. The battery technologies most frequently utilized in grid-sized BESSs are lead acid, lithium-ion, nickel-metal hydride, sodium-sulfur, and flow. Each battery technology’s specific chemical reaction and performance characteristics (see Table 1) are as follows:

Lead Acid batteries store chemical energy in the potential difference between the pure lead on the negative side and the lead dioxide on the positive side within the aqueous sulfuric acid. Lead-acid battery types include flooded and valve — regulated. Lead-acid batteries have a lower energy density, specific energy, and cycle duration characteristics. They have good charge/discharge efficiency and self-discharge characteristics.

Lithium-ion batteries are electrochemical types that are characterized by the transfer of lithium ions through electrolytes between the intercalated lithium compound positive electrode and graphite negative electrode during the charge and discharge reactions. Lithium-ion batteries have a great energy density, charge/discharge efficiency, and self-discharge characteristics. They have good specific power and cycle duration characteristics.

Nickel-metal hydride batteries are electrochemical types that are characterized by the transfer of hydrogen through the alkaline electrolyte between the nickel hydroxide positive electrode and hydrogen-absorbing alloy negative electrode. Nickel-metal hydride batteries have great specific power and cycle duration characteristics. They have good energy density and charge/discharge characteristics and poor self-discharge characteristics.

Sodium-sulfur batteries are electrochemical types that are characterized by using liquid sulfur for positive electrode with a molten sodium for anode with a ceramic separator between them. For the sodium-sulfur battery to function, it must be maintained at temperatures between 470°F (245°C) and 660°F (350°C). Sodium-sulfur batteries have exceptional specific power and self-discharge characteristics. They have great cycle duration and charge/discharge efficiency characteristics and good energy density characteristics.

Flow batteries have one (or more) chemical component(s) that is dissolved in a liquid solution (see Figure 3). The chemical solutions are typically stored in tanks and separated by a membrane. The overall battery-specific power is determined by tank size. Flow batteries have exceptional cycle duration and self-discharge characteristics as well as lower energy density, specific power, and charge/discharge efficiency characteristics.

Lead acid, nickel-metal hydride, and sodium-sulfur batteries were primarily used before 2010. With the development of lithium-ion battery technology and the substantial cost reduction to create them in recent years, lithium-ion batteries are utilized in 90% of grid-sized BESSs. A limiting factor for lithium-ion battery expansion in the future is the availability of rare earth to make the battery. Sodium-ion and flow batteries are emerging energy storage technologies that are made of more readily available materials and may prove more attractive as the technologies are further developed.

Battery Technical Standards

The emerging BESS market has experienced numerous fires and explosions, resulting in catastrophic damage. Recently, numerous safety standards have been developed to reduce the risk of fire and explosions. A BESS installation must meet the local building codes, utility regulations, and industry standards. The utility regulations will need to be obtained from the utility company the batteries are connecting to. Four industry safety standards developed to minimize the hazards associated with BESSs are as follows:

International Fire Code (IFC), Chapter 12, Energy Systems — This standard establishes that storage batteries, prepackaged stationary storage battery systems, and pre-engineered stationary storage battery systems shall be segregated into stationary battery bundles not exceeding 50 kWh each, and each bundle will be spaced a minimum of 3 feet apart and from the building wall. The IFC code also requires battery charges be listed in accordance with UL1564 and inverters are listed in accordance with UL1741.

National Fire Protection Agency (NFPA) 855 – Standard for the Installation of Stationary Energy Storage — This standard establishes the requirements for design, construction, installation, commissioning, operation, maintenance, and decommissioning of stationary energy storage systems. This standard applies to battery installation over 70 kWh.

UL 9540 – Standard for Safety Energy Storage Systems and Equipment — This standard establishes that electrical, electro-chemical, mechanical, and thermal energy storage systems operate at an optimal level of safety. It also establishes safety requirements for the integrated components of an energy storage system.

UL 9540A – Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems — Establishes quantitative data to characterize potential battery storage fire events. It also establishes battery storage system fire testing on the cell level, module level, unit level, and installation level.

These recently developed standards are still evolving and will see revisions in the future. Many additional standards need to be reviewed, understood, and incorporated into a battery energy storage system facility. Careful investigation of all standards needs to be performed before undertaking the design, construction, installation, and operation of a BESS.

BESS Layout

A BESS layout has several batteries in series to achieve a specific DC voltage (see Figure 3). The string of batteries is connected through a DC/AC inverter/charger. Typically, there will be multiple strings of batteries and DC/AC charges to reduce the energy and power lost if there is a battery or inverter/charger failure. Depending on the AC voltage coming off the DC/AC inverter/charger, a transformer may be needed to adjust the voltage to match the low-voltage AC bus. Similarly, solar power panels can be tied into the low-voltage AC bus through a DC/AC inverter and transformer. The low-voltage AC bus is connected to the utility bus through a step-up transformer and a disconnect. With the solar PV panels, batteries, and diesel generator, a small microgrid power distribution system can maintain power to the loads when the utility grid disconnect is opened.

An alternative design would have a DC bus. If the majority of the solar PV power is stored in the batteries before distribution to the utility grid, transformer energy loss can be reduced by having solar PV power and the batteries connected on a DC bus.

Modular Versus Building BESS Arrangement

This author’s first BESS project was a building type (see Figure 1). The batteries were arranged in rows with a DC/AC inverter/charger at the end of the row. The batteries were arranged similar to data center servers with the battery blowers drawing cold air from the cold aisle and blowing the warm air into the hot aisle. The HVAC system returned air from the hot aisle, conditioned it, and supplied it into the cold aisle. The building was large, and there were many rows of batteries.

The modular BESS has small modules (containers) that contain either the batteries or the DC/AC inverter/charger (as shown in the lead image). The battery modules would be provided with dedicated air conditioning units. These modules would be installed in a field on concrete pads with the wiring being connected between them. Similar to the building, the modular battery configuration is similarly set up of a hot aisle/cold aisle arrangement.

The modular arrangement advantage is the module engineering is already performed by the BESS supplier, resulting in lower cost, better risk mitigation from fire, and modularity. The advantage of the building arrangement is that it offers a small area footprint for the same capacity, easier security, a more robust air conditioning system, and better system augmentation when batteries start losing their capacity.

Both arrangements will be challenged to meet the evolving NFPA and UL standards for fire safety. Future changes may include more robust battery thermal management in-rack cooling water systems and other safety features.

It is important to perform an analysis of both the modular and building arrangements to determine which is better for each specific application.

Conclusion

Grid-sized BESSs will be an integral part of future utility power distribution systems. This industry will have many challenges, including developing batteries that have a higher energy density, are economically viable, manufactured with more readily available materials, and improved safety. Along with utility power distribution systems, grid-sized BESSs will see substantial transformation during the next several decades.

References

Jennifer E. Leisch, Ph.D., Llya Chernyakhowskiy, “Grid-Scale Battery Storage – Frequently Asked Questions,” NREL TP-6A20-74426. Golden, CO. NREL. September 2019.

International Renewable Energy Agency (IRENA), “Utility-Scale Batteries – Innovation Landscape Brief,” ISBN 978-92-9260-139-3. Abu Dhabi, Saudi Arabia. 2019.

Energy Storage Association (ESA), “Why Energy Storage: Technologies, Batteries.” Washington, D.C., 2021.

U.S. Energy Information Administration (EIA), “Battery Storage in the United States: An Update on Market Trends.” Washington, D.C., July 2020.

Erik D. Spoerke, Ph.D., “Molten Sodium Batteries: Promise for Advancing Grid-Scale Battery Utility,” SAND2019-2719C. Sandia National Laboratories. Albuquerque, New Mexico. March 2019.

Prachi Patel, Peter Fairley, “Sodium-Ion Batteries Poised to Pick Off Large-Scale Lithium-Ion Applications.” Institute of Electrical and Electronic Engineers (IEEE). New York, New York. March 2021.

Laurie Florence, Harry P. Jones, Alex Liang, “Safety Issues for Lithium-Ion Batteries.” Underwriters Laboratory (UL). Northbrook, IL. 2013.

Paul Brazis, Adam Barowy, Robert Backstrom, Pravinray Gandhi, Alvin Wu, Carl Wang, “Evaluating the Safety of Energy Storage Systems: UL9540A.” Underwriters Laboratory (UL). Northbrook, Illinois. November 2018.

Andrew Klock, Brian O’Connor, “NFPA Energy Storage Safety Training.” National Fire Protection Association (NFPA). Quincy, Massachusetts. February, 2017.

Samuel S. Dannaway, “The Rise in Popularity of Battery Storage Systems for PV Systems has Led to a Rise in Fire Safety Concerns.” FPE Corner. April 2019.