Back 2 Basics

Ammonia Chiller Replacement for a High-Performance Health Care Central Plant Using Construction Management Project Delivery

SCROLL

Project Delivery Method: Construction management at risk (CM) with guaranteed maximum price (GMP)

Owner Team: Hospital president, owner representative (consultant), project manager of capital project, and facility manager (in-house staff)

Project Delivery Team: CM project manager; job superintendent; mechanical-electrical coordinator; and plumbing, electrical, structural, fire protection, safety, and security consultants

HVAC Project Team: HVAC project manager-subcontractor; building automation system (BAS) technician (in-house staff); BAS technician-subcontractor; operations and maintenance (O&M) technician (in-house staff); third-party commissioning consultant (CxC); and testing, adjusting, and balancing (TAB) technician

Refrigeration 2018 ASHRAE Handbook: “Ammonia Refrigeration Systems,” Chapter 2

HVAC Application 2019 ASHRAE Handbook: “Health Care Facilities,” Chapter 9

Systems 2020 ASHRAE Handbook: “HVAC System Analysis and Selection,” Chapter 1, and “Central Cooling and Heating,” Chapter 3

Project Type: Infrastructure enhancement

Other References: Refer to the codes and standards in the back of each ASHRAE Handbook for additional reference. International Institute of Ammonia Refrigeration (IIAR) Bulletin 108, “Water Contamination in Ammonia Refrigeration Systems,” IIAR Bulletin 109, “IIAR Minimum Safety Criteria for a Safe Ammonia Refrigeration System,” IIAR Bulletin 110, “Start-Up, Inspections and Maintenance of Ammonia Mechanical Refrigerating Systems,” and IIAR Bulletin 114, “Identification of Ammonia Refrigeration Piping and System Components.” Also reference Construction Management Association of America (CMAA) and IIAR materials

DESIGN INTENT DOCUMENT (DID)

- The HVAC system selection and design intent are based on the process outlined in ASHRAE Handbook 2020, Chapter 1, “HVAC System Analysis and Selection,” and include the following:

- Research the concept of furnishing and installing an ammonia chilled water plant considering existing conditions, first cost, and operating cost

- Research and report on the environmental benefits of ammonia versus ongoing traditional refrigerant usage

- Establish and implement the hospital building program’s goals and additional goals

- System constraints and constructability constraints

- The finalized system selection shall be central cooling plant replacement of 2- to 200-ton antiquated electric chillers with 2- to 200-ton ammonia chillers

- New automatic temperature controls (ATCs) furnished with each chiller control panel, a BACnet interface, an internet interface, and safety and security systems associated with the ammonia chiller plant operation. New control systems will be interfaced with the existing BAS system and the existing computerized maintenance management software (CMMS) system

- Program & Project Goals:

- The aforementioned functional goals and environment goals of ozone depletion potential (ODP) of 0 and a global warming potential (GWP) of 0

- Budget goals: first cost, operating cost, and global warming difference

- Timeline goal(s): complete prior to the start of air conditioning season (May 1)

- Management goals: In-house management; capital projects management; and mechanical/electrical operation, and maintenance management of ammonia

- Utility availabilities: existing electrical power, central plant chilled water system distribution, and BAS

- Existing conditions: Remove and replace the antiquated electrical chillers and chilled water pumps

DESIGN CRITERIA DOCUMENT

- The HVAC design criteria shall be in sync with the project delivery method and the owner’s project requirements

- A new central chilled water plant will replace the existing units while reusing recently replaced high-performance cooling towers

- Replace antiquated constant volume chilled water pumps and head-pressure controls with new chilled water pumps with variable frequency drive (VFD) controls

- The design team shall provide contract drawings and specifications coordinated with equipment weight, electric, and plumbing criteria for the CM project manager to solicit contractor bids

- Field fabrication piping drawings shall become the record drawings at closeout

- New equipment shall be furnished with O&M manuals immediately following the approval of this equipment for the O&M staff to begin their training

- The preventive maintenance work orders shall be uploaded to the in-house O&M CMMS

- The design team and CM firm will refer to IIAR and ASHRAE guidelines for design, construction, and commissioning best practices

- Implement ASHRAE Guideline GPC-22, “Instrumentation for Monitoring Central Chilled Water Plant Efficiency”

- The O&M staff shall receive specialized training associated with the use of ammonia refrigeration as well as standard central chiller plant training

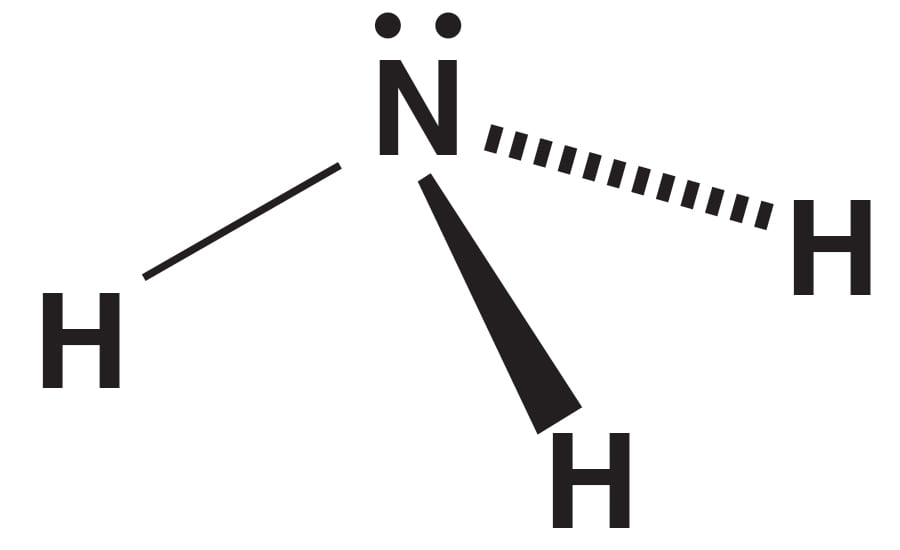

Image courtesy of WSP USA

The chemical makeup of ammonia.

Design Engineer’s Punchlist

Project Delivery Method:

- Design-Build (D-B)

- Integrated Project Delivery (IPD)

- Construction Management at Risk (CM) with Guaranteed Maximum Price (GMP)

- Design-Bid-Build (D-B-B)

Owner Team:

- Hospital President

- Building Program Committee

- Safety and Security Consultant

- Project Manager of Capital Projects

Project Delivery Team:

- D-B Project Manager

- CM Project Manager

- Architect

- Job Superintendent

- Mechanical-Electrical Coordinator

- Safety and Security Consultant

HVAC Project Team:

- HVAC Project Manager-Subcontractor

- HVAC Technician (in-house staff)

- BAS Technician (in-house staff)

- Third-Party Commissioning Consultant (CxC)

- Energy Consultant

2018 ASHRAE Handbook-HVAC Application

- Ammonia Refrigeration Systems, Chapter 2

- Cryogenics, Chapter 47

- Ventilation of Industrial Environment, Chapter 48

2020 ASHRAE Handbook-HVAC Systems and Equipment

- HVAC System Analysis and Selection, Chapter 1

- Decentralized Cooling and Heating, Chapter 2

- Central Cooling and Heating Plant, Chapter 3

- Compressors, Chapter 38

- Liquid Chiller Systems, Chapter 43

Project Type:

- New Construction

- Addition

- Renovation

- Shell & Core

- Infrastructure (central cooling)

References:

- 2017 ASHRAE Handbook – Fundamentals

- 2018 ASHRAE Handbook – Refrigeration

- 2019 ASHRAE Handbook – HVAC Applications

- 2020 ASHRAE Handbook – HVAC Systems and Equipment

Other References:

- Codes and Standards at the End of ASHRAE’s Handbooks

- ASHRAE Indoor Air Quality Guide: Best Practice for Design, Construction, and Commissioning

- IIAR Bulletins 108, 109, 110, and 114

- NFPA 101

DESIGN INTENT DOCUMENT (DID)

- Research into the Application of Ammonia Refrigeration

- Hospital Building Program Goals and Additional Goals

- New Automatic Controls Temperature Controls (ATC) Furnished with each Chiller, BACnet Interface, Internet Interface, an Existing BAS Interface, and Existing CMMS System Interface

- Functional Goals: Refer to Chapter 1, 2019 Handbook

- Budget Goals: First Cost, Operating Cost, Global Warming Difference

- Timeline Goal(s): Occupancy Due Date — August

- Management Goals: Outsource Management and Capital Projects Management

- Utility Availabilities: Existing Electrical Power and BAS

- Existing Conditions: Remove and Replace Central Chillers and Associated Chilled Water Pumps

DESIGN CRITERIA DOCUMENT

- The HVAC Design Criteria Shall Be in Sync with the Project Delivery Method and Owner’s Project Requirements

- A New Central Chillers shall Replace the Existing Units to Significantly Reduce Ozone Depletion Potential and Global Warming Potential

- The New Chillers and New Cooling Towers will Reduce the Carbon Footprint

- The Design Team Shall Provide Contract Drawings and Specification Coordinated with Equipment Weight, Electric, and Plumbing Criteria for the CM Project Manager to Solicit Contractor Bids

- Field Fabrication Drawings Shall Become the Record Drawings at Closeout

- Heat Rejection Equipment Shall Be Furnished with O&M Manuals

- The Preventive Maintenance Work Orders Shall Be Uploaded to the In-House O&M CMMS System

- The Design Team and CM Firm will Refer to IIAR and ASHRAE Guidelines for Design, Construction, and Commissioning Best Practices

- Implement ASHRAE Guideline GPC-22, Instrumentation for Monitoring Central Chilled Water Plant Efficiency

- The O&M Staff Shall Receive Specialized Training Associated with the Use of Ammonia Refrigeration as well as Standard Central Chiller Plant Training

- ANSWERS marked in blue -

Project Delivery Method:

- Design-Build (D-B)

- Integrated Project Delivery (IPD)

- Construction Management at Risk (CM) with Guaranteed Maximum Price (GMP)

- Design-Bid-Build (D-B-B)

Owner Team:

- Hospital President

- Building Program Committee

- Safety and Security Consultant

- Project Manager of Capital Projects

Project Delivery Team:

- D-B Project Manager

- CM Project Manager

- Architect

- Job Superintendent

- Mechanical-Electrical Coordinator

- Safety and Security Consultant

HVAC Project Team:

- HVAC Project Manager-Subcontractor

- HVAC Technician (in-house staff)

- BAS Technician (in-house staff)

- Third-Party Commissioning Consultant (CxC)

- Energy Consultant

2018 ASHRAE Handbook-HVAC Application

- Ammonia Refrigeration Systems, Chapter 2

- Cryogenics, Chapter 47

- Ventilation of Industrial Environment, Chapter 48

2020 ASHRAE Handbook-HVAC Systems and Equipment

- HVAC System Analysis and Selection, Chapter 1

- Decentralized Cooling and Heating, Chapter 2

- Central Cooling and Heating Plant, Chapter 3

- Compressors, Chapter 38

- Liquid Chiller Systems, Chapter 43

Project Type:

- New Construction

- Addition

- Renovation

- Shell & Core

- Infrastructure (central cooling)

References:

- 2017 ASHRAE Handbook – Fundamentals

- 2018 ASHRAE Handbook – Refrigeration

- 2019 ASHRAE Handbook – HVAC Applications

- 2020 ASHRAE Handbook – HVAC Systems and Equipment

Other References:

- Codes and Standards at the End of ASHRAE’s Handbooks

- ASHRAE Indoor Air Quality Guide: Best Practice for Design, Construction, and Commissioning

- IIAR Bulletins 108, 109, 110, and 114

- NFPA 101

DESIGN INTENT DOCUMENT (DID)

- Research into the Application of Ammonia Refrigeration

- Hospital Building Program Goals and Additional Goals

- New Automatic Controls Temperature Controls (ATC) Furnished with each Chiller, BACnet Interface, Internet Interface, an Existing BAS Interface, and Existing CMMS System Interface

- Functional Goals: Refer to Chapter 1, 2019 Handbook

- Budget Goals: First Cost, Operating Cost, Global Warming Difference

- Timeline Goal(s): Occupancy Due Date — August

- Management Goals: Outsource Management and Capital Projects Management

- Utility Availabilities: Existing Electrical Power and BAS

- Existing Conditions: Remove and Replace Central Chillers and Associated Chilled Water Pumps

DESIGN CRITERIA DOCUMENT

- The HVAC Design Criteria Shall Be in Sync with the Project Delivery Method and Owner’s Project Requirements

- A New Central Chillers shall Replace the Existing Units to Significantly Reduce Ozone Depletion Potential and Global Warming Potential

- The New Chillers and New Cooling Towers will Reduce the Carbon Footprint

- The Design Team Shall Provide Contract Drawings and Specification Coordinated with Equipment Weight, Electric, and Plumbing Criteria for the CM Project Manager to Solicit Contractor Bids

- Field Fabrication Drawings Shall Become the Record Drawings at Closeout

- Heat Rejection Equipment Shall Be Furnished with O&M Manuals

- The Preventive Maintenance Work Orders Shall Be Uploaded to the In-House O&M CMMS System

- The Design Team and CM Firm will Refer to IIAR and ASHRAE Guidelines for Design, Construction, and Commissioning Best Practices

- Implement ASHRAE Guideline GPC-22, Instrumentation for Monitoring Central Chilled Water Plant Efficiency

- The O&M Staff Shall Receive Specialized Training Associated with the Use of Ammonia Refrigeration as well as Standard Central Chiller Plant Training