SCROLL

FEATURE

Roundtable Discussion: Chilled Beam Applications in Diverse Building Types and Climate Zones

Active chilled beams can be applied in various building types to achieve a wide range of sustainability goals.

SCROLL

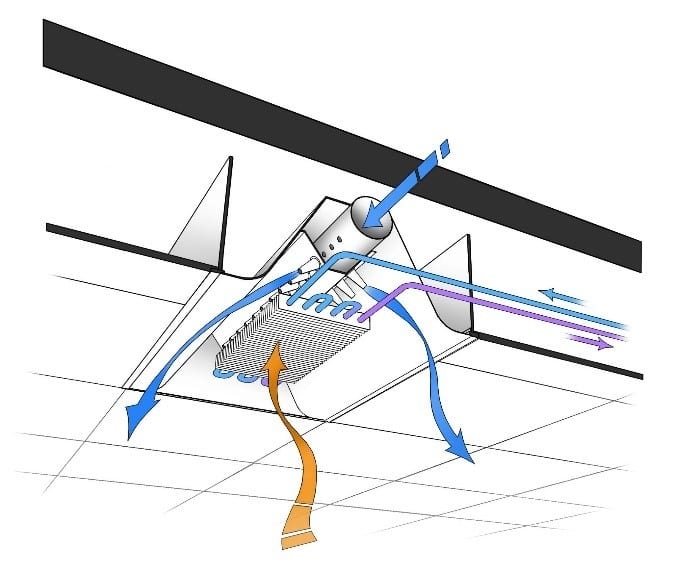

Active chilled beams are HVAC devices composed of primary air ducted supply, hydronic coils, and diffuser slots that provide localized sensible cooling to the space1. Primary air is induced through nozzles, which creates a negative pressure to force room air convection across the coils1. Active chilled beams can be applied in various building types to achieve a wide range of sustainability goals. Active chilled beams also are adaptable to different climate characteristics, although additional attention may be required for infiltration and humidity control in hot and humid regions.

In this article, three industry practitioners and mechanical consulting engineers from Affiliated Engineers Inc. (AEI) — Robin Graves, Jessica Mangler, and Melody Wang — share their experience and key lessons learned with active chilled beam design from different regions of the U.S.

Panelists

Robin Graves

Practicing out of AEI’s headquarters in Madison, Wisconsin, Robin Graves serves as a mechanical engineer and department facilitator, providing HVAC systems leadership, consulting, and design for more than 16 years. With an emphasis on high-performance systems and sustainable design, she has implemented chilled beam technology in diverse facility types comprising the higher education, health care, and federal government sectors.

Jessica Mangler

Jessica Mangler works in AEI’s Seattle office, providing 13-plus years of experience in mechanical systems design. She has led the mechanical designs of multiple chilled beam projects in higher education, research/teaching labs, and health care facilities. Most recently, Mangler’s projects have focused on using the unique decoupled cooling abilities of chilled beam technology to help projects achieve net-zero energy and decarbonization goals.

Melody Wang

An integral member of AEI’s office in Gainesville, Florida, Melody Wang focuses on sustainable and innovative mechanical designs for higher education and research development clients. She has several chilled beam projects in design, construction, and operation and has successfully conducted energy models for those buildings to achieve sustainability ratings.

What types of buildings benefit from active chilled beam designs?

Wang: Active chilled beams are advantageous for a variety of building types. In warmer climates, offices with curtain wall designs often have high sensible loads. Utilizing active chilled beams in spaces with low latent load and low ventilation requirements can help decouple cooling from the air system and hydraulically cool the space with the chilled beam coils. While laboratories, especially those with fume hoods, are not conventional candidates for implementing active chilled beams, this technology can actually help reduce airflow and improve energy use in lab environments when they are selected based on the appropriate air change and makeup air requirements related to the fume hoods.

Graves: Chilled beams can be used in nearly any building type that has a higher sensible load than latent load for most spaces. If a process cooling water system is already needed for the building to serve fan coil units, radiant systems, laboratory equipment, controlled environmental rooms, or autoclave/sterilizer condensate cooling, then chilled beams can be added to the system design with minimal impact.

Mangler: Chilled beams can frequently be used in lab buildings, but it’s important to note that chilled beams are not the appropriate solution for biocontainment labs or labs with high latent levels. Applying chilled beams is ideal in labs that are not ventilation-driven and have high sensible loads. We consider a lab to be ventilation-driven when exhaust requirements (fume hoods, snorkels, etc.) drive exhaust airflow rates beyond 6 air changes (ACH).

When we have a lab with these conditions (6 ACH max), ventilation air to the chilled beams is adequate to meet the lab’s makeup air requirements and some of the lab’s cooling load. The remaining cooling load is met with the hydronic performance of the chilled beam.

During the early design stages of a lab project, we recommend communicating with the owner, architect, and lab planner about how lab equipment and fume hood density impact the mechanical design. One successful way to communicate how a lab can be designed with the 6 ACH limitation is by equating this limitation to a fume hood per area formula. For example, a lab with 10-foot-6-inch ceilings, designed with 6-foot fume hoods and operating at 80-90 fpm with standard open sash heights equates to one fume hood for every 650-700 square feet of the lab area.

FIGURE 1: An illustration of active chilled beams.

Image courtesy of Affiliated Engineers Inc.

What are some obstacles to using active chilled beams?

Wang: For owners who are not familiar with the active chilled beam system, or those who have had negative experiences with operating active chilled beams in their facilities, it may be difficult to convince them to use active chilled beams in their projects. A thorough review is necessary to fully understand their concerns and to solve the potential downfall. Active chilled beams also present themselves as a “cost add” compared to conventional diffusers. When looking at the building project holistically, however, active chilled beams may present a net savings of the first cost by potentially downsizing the air handlers and ductwork sizes.

Graves: Chilled beams weigh more than a traditional duct and diffuser. This needs to be accounted for with the structural design. The installation generally takes two people, and the installation sequence needs to be coordinated with the ceiling contractor. We recommend the chilled beams are installed first and raised just above the ceiling height. Chilled beam hangers typically have hangers that can be adjusted in all three dimensions. This allows the mechanical contractor to fine-tune the final location after the ceiling is installed.

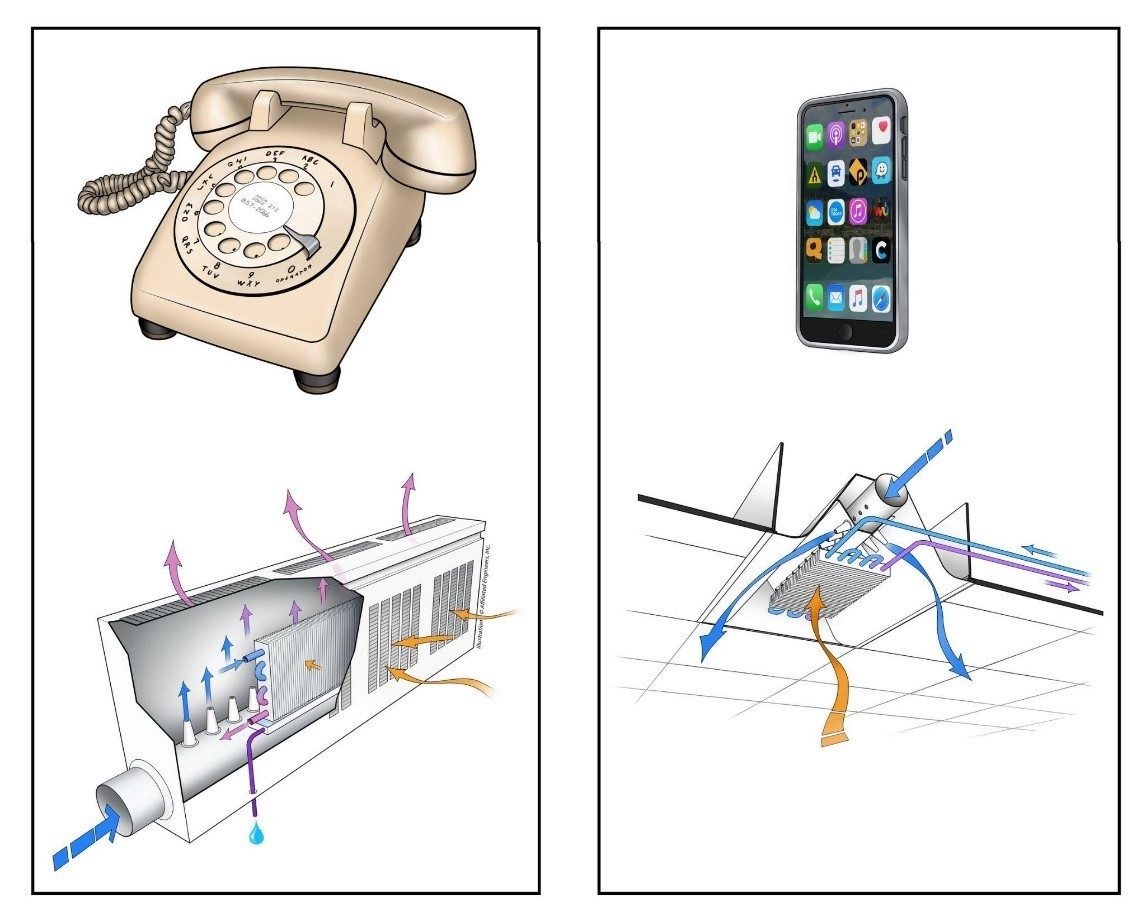

Mangler: Some owners have not had the opportunity to install chilled beams in their buildings, so chilled beams can be viewed as a new, unproven technology that their facilities staff may not have the necessary experience to maintain. To get over this hurdle, we work to connect these owners with other clients who have experience with chilled beams. These connections turn into great opportunities for all parties to share experiences about chilled beams, the benefits of using this high-performance technology, and so much more.

FIGURE 2. A comparison of modern and traditional technology.

Image courtesy of Affiliated Engineers Inc.

What is the driving force to apply chilled beams in current or future projects?

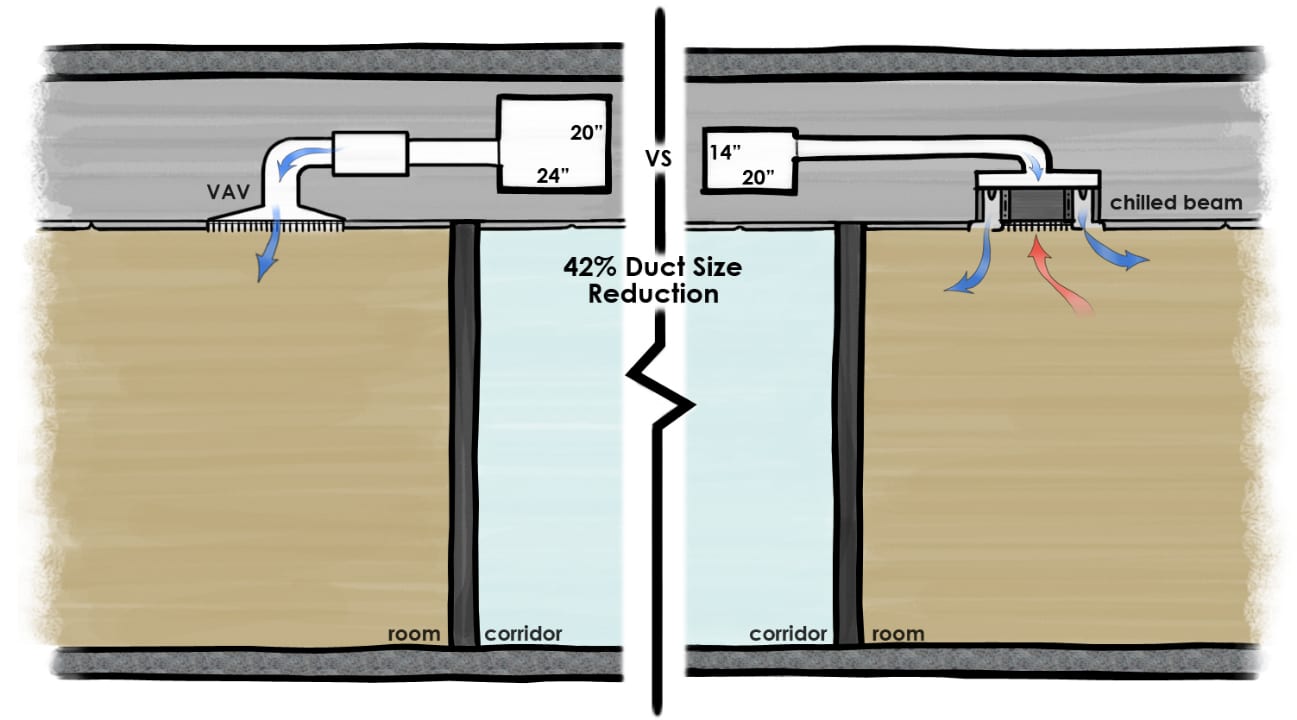

Graves: Chilled beams can often provide significant energy savings of up to 30% compared to a traditional VAV system. These savings are usually seen at the utility plant, where there are greater opportunities for energy-saving measures.

When the above-ceiling space is tight, chilled beams can be a good option. Chilled beams can deliver the same amount of cooling to a space while using less ceiling space. Water is a more efficient heat conductor than air.

FIGURE 3. Chilled beam and duct size reduction.

Image courtesy of Affiliated Engineers Inc.

Mangler: Chilled beams can offer a lot of flexibility for a building’s design. In many of our current projects, we often hear requests for buildings that are adaptable and flexible for future changes. We also know that most projects look for cost savings at some point in the design. While these may seem like competing goals, chilled beams can be designed and implemented in a “plug and play” style that helps meet both goals.

For example, in a university lab building, a specific lab can be occupied by many different faculty members and/or research scientists over the life of the building. Each researcher may have different uses for the lab that impact the lab’s equipment loads (sensible cooling loads). In these labs, we reserve ceiling space for additional chilled beams to be added in the future and call them “chilled beam ready zones.” Duct and piping taps are provided to these zones, off adjacent mains, so that chilled beams can be readily added in the future. This strategy allows chilled beams to be added in the future with minimal disruption to adjacent spaces and saves the first cost for the project.

Wang: Public and private clients want to focus on building sustainability and innovative design. Active chilled beams help them differentiate their facility from conventional heating and cooling solutions. When compared to an ASHRAE baseline building, a chilled beam building surpasses categories in chilled water consumption, fan energy usage, and overall building energy cost. The saving percentage in comparison to ASHRAE baseline buildings is important to meeting state and local standards, as well as achieving sustainable recognition, such as LEED certifications. For a building owner, those projections also translate to fiscal savings.

Can we use chilled beams in labs or hospitals?

Mangler: Chilled beams can be used in some health care settings, but careful attention must be made to local regulations and the type of health care building. In the state of Washington, we retrofitted a cancer care clinic’s existing 100% outside air-handling system with upgrades that enabled chilled beams to be installed in an associated immunotherapy clinic. In health care buildings with other occupancy types, however, state health care regulations have prevented chilled beams from being installed. When determining the mechanical system for a health care facility, local regulations must be carefully researched, and the mechanical system type needs to be discussed with the appropriate authorities having jurisdiction (AHJ).

Wang: While the active chilled beam system has its place in labs and hospitals, we recommend considering additional factors during the design process. Laboratory spaces will have air change requirements, and the minimum air change rate should be one of the factors in determining minimum primary air, in addition to latent load airflow and minimum ventilation airflow. Similar to a latent load drive conference room, where chilled beams would not be beneficial, an air change drive laboratory will not see the energy savings potential from chilled beam implementation. For laboratory spaces with fume hood exhaust, supply makeup air is another factor to consider when determining minimum primary air. Laboratories and hospitals also have localized filtration requirements, which may affect the decision on chilled beam usage.

Graves: We have used chilled beams in both laboratory and health care applications, but it is much more widely used in laboratories. Chilled beams are a good application for dry research laboratories or other high sensible cooling load spaces. Ideally, they can be paired with a reduction of air changes to suite the specific spaces. This maximizes energy savings and provides a large reduction in air-handling unit and ductwork costs. It’s important to review the sensible and latent load when selecting the beams as well as heating output if using four-pipe beams.

FIGURE 4. FSU Earth, Ocean, and Atmospheric Science (EOAS) building with active chilled beams.

Image courtesy of Florida State University

What types of ceiling applications are limiting for chilled beams?

Graves: Chilled beams come in a variety of sizes. While a traditional chilled beam is a 2-foot-by-4-foot size, they now can come in 1-foot widths and extra-long 10-foot sizes for both two-pipe and four-pipe devices. They can be installed in acoustical lay in ceilings, hard lid ceilings, or custom wood/metal panel ceilings. The 1-foot width beams are often used in more architecturally sensitive spaces and exposed ceilings. For exposed ceilings, coanda wings are used to ensure proper airflow and mixing by mimicking the benefits of having a surface for the primary air to follow after leaving the chilled beam.

Mangler: Providing coanda wings for chilled beams mounted in open-ceiling areas is necessary, as they ensure proper airflow patterns to the beam. These wings also impact how the chilled beams visually appear in the ceiling plane, so it’s important to communicate this feature to architectural teams.

The mounting height of chilled beams is also critical and may be limiting for some zones. Most manufacturers will report derated capacities for chilled beams mounted more than 14 feet above the floor.

Wang: Custom ceilings, such as sculptural wood ceilings, may not be suitable for chilled beam application. During the design process, the engineer should collaborate with the owners and the architects for aesthetic expectations and maintenance access plans. At the University of Florida Malachowsky Hall for Data Science and Information Technology, we have a conference room with a high glazing load, but the ceiling is not suitable for chilled beam installation. We applied the chilled beam dry coil principle and used a fan coil unit as supplemental cooling on the chilled beam water loop.

FIGURE 5. University of Florida Malachowsky Hall for Data Science and Information Technology.

Image courtesy of Bohlin Cywinski Jackson

What are some lessons you learned from past chilled beam projects?

Mangler: Be mindful of the cooling capacity you can get out of a passive chilled beam relative to an active chilled beam and evaluate performances from multiple manufacturers.

Wang: Make sure a functional test is performed by the commissioning agent prior to substantial completion of the building. Make sure the building exterior is properly sealed to avoid condensation issues in exterior rooms.

Graves: Be sure to get selections from multiple chilled beam manufacturers. There are differences in the capacities and options provided from different manufacturers. It’s better to be conservative and design with a beam capacity that at least three manufacturers can meet.

Do you typically use two-pipe or four-pipe chilled beams?

Wang: In the cooling-dominant southeast climate, we typically use two-pipe chilled beams downstream of air terminal boxes, which handle the space reheat.

Graves: It depends on the project. If occupants will regularly be sitting along the exterior for extended periods of time, and it’s a cold climate, we recommend perimeter heating. If there isn’t an opportunity to provide perimeter heating, we turn to four-pipe chilled beams to provide both heating and cooling to the space. Four-pipe chilled beams are ideal in spaces that have similar heating and cooling loads. We will typically schedule two-pipe chilled beams for heavily cooling-driven spaces, even if other beams in the building are four-pipe chilled beams.

Mangler: We typically design around four-pipe chilled beams during the early stages of the project, so that all of the zone’s heating and cooling loads are handled at the beams. This is a flexible approach that simplifies zoning for the project. If the mechanical system is presented with cost challenges during mid-design, we evaluate the pros and cons of switching to two-pipe chilled beams with the owner. At this stage, the design team is set up for a productive discussion about zone control and can react to these decisions with minimal redesign effort.

Are chilled beams better in certain climates than others?

Mangler: With proper controls, chilled beams can be implemented in any climate zone. Reacting to latent loads can be challenging for chilled beams, so the control strategy needs to be carefully studied. In the Pacific Northwest, with its relatively mild climate, we have found ways to provide zones with natural ventilation and chilled beams. The risk for condensation at the chilled beams is also significantly limited with a strategic controls approach. This design, although suitable for the Pacific Northwest, would not be as successful in relatively more humid and hotter climates.

Wang: The benefit of chilled beams is to reduce central cooling and heating equipment size by conditioning sensible, load-intense spaces with local hydronic coils. The sensible load can be from an envelope or an internal source. The engineer should look at the design degree-days of the climate and make the decision of whether chilled beam application is the right option in terms of life-cycle cost. Different design considerations should be made with different climates as well. For example, most Florida regions have more than 2,50 cooling degree days, which makes chilled beams an attractive option; however, Florida is also known for its hot and humid weather. The dehumidification design temperature often surpasses the cooling design temperature in terms of enthalpy. Building owners are often concerned about condensation issues caused by high humidity. As solutions, vestibules can be added to the exterior entrances, and buildings can be designed slightly positively pressurized to keep the humidity out. The natural ventilation solution that is suitable for the Pacific Northwest climate that Jessica [Mangler] mentioned may not be as appropriate for the southeast.

Graves: We’ve successfully implemented the use of chilled beams in most climates. If a process cooling water loop is available and the ventilation air is dehumidified for occupant needs, chilled beams can used for the majority of sensible driven cooling and/or heating spaces. We typically use a 58°F process cooling water loop which is 3°-4° above the space dew point to avoid any chance of condensation on the beam.

Reference:

1. Woollett, John Rimmer, Julian. (2015). REHVA Guidebook No. 21 - Active and Passive Beam Application Design Guide. REHVA, the Federation of European Heating, Ventilation and Air Conditioning Associations. Retrieved from

https://app.knovel.com/hotlink/toc/id:kpREHVAGH2/rehva-guidebook-no-21/rehva-guidebook-no-21

Herb Woerpel

Herb Woerpel is editor-in-chief of Engineered Systems. Contact him at woerpelh@bnpmedia.com.