FEATURE

SCROLL

HVAC Savings in Uncertain Economic Times

Ultraviolet energy can make workplaces safer, healthier, and more productive.

Always attuned to operational costs, today’s commercial facility engineers are facing once-in-a-lifetime budgetary uncertainties wrought by the COVID 19 pandemic, including decreased occupancy rates, record inflation, and a slowing economy.

Cutting costs is paramount now, and many facilities are targeting HVAC expenses, as this category can represent upward of 40% of building overhead. Well known for inactivating the SARS-CoV-2 virus, germicidal UV technology is a go-to strategy to shave 20% off HVAC energy costs by boosting coil-heat transfer efficiency.

Since the early 1990s, property managers have been drawn to germicidal UV-C technology for its tangible improvements in HVAC heat-transfer efficiencies, decreased coil pressure drop, and the associated energy savings. The pandemic has offered real-world proof of how UV-C can inactivate infectious bacteria and viruses and, at the same time, served to highlight the public’s understanding of — and appreciation for — this health-safety necessity.

In addition to the substantial operational savings, UV-C fixtures installed in air handlers or HVAC ducts make workplaces safer, healthier, and more productive. This offers a significant value to tenants uneasy about returning to work.

However, with economic contraction and rising inflation, the UV-C wavelength’s ability to slash HVAC operating expenses is top of mind for facility engineers. Building managers and owners can reap savings on two tiers.

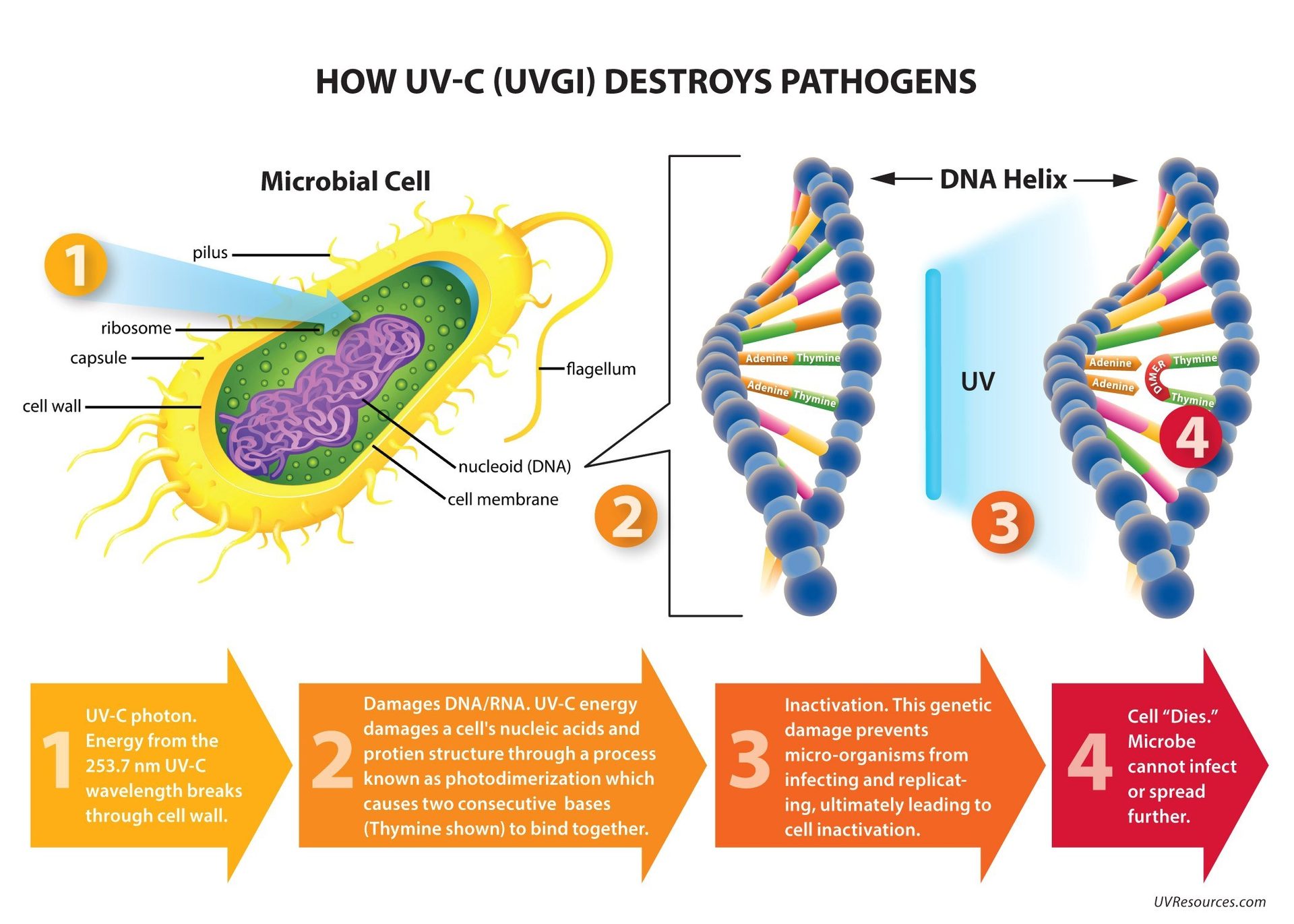

FIGURE 1: How UV-C works, by the numbers.

Images courtesy of UV Resources

Tier 1: Coil Cleaning/HVAC Efficiency

Germicidal UV-C technology’s first tier of savings is boosting HVAC efficiency levels. Adding UV-C energy alone doesn’t save energy; rather, it restores coil and airflow performance to near its original design capacity.

As HVACR equipment ages, microbial fouling or contaminant buildup decreases coil-heat transfer efficiency and degrades the system’s ability to remove heat. Once this buildup accumulates, it obstructs efficient heat removal — sort of like a barrier between the air and the cooling coil. As efficiency levels drop, humidity ratios increase — as not enough water is removed by the cooling coil, which results in poor IAQ levels and occupant complaints.

As heat transfer performance decreases, operators are forced to compensate with more energy-intense adjustments to try and meet demand, such as increasing fan speeds and decreasing chilled water temperatures. Once installed, UV-C alters the microbe’s genetic DNA/RNA so that cells can no longer reproduce. As UV-C breaks down the organic build-up on the coil, heat transfer efficiency improves and the pressure drop falls.

ASHRAE TC 2.9 — the technical committee responsible for studying Ultraviolet Air and Surface Treatment — conducted independent research that found the germicidal wavelength yielded an average pressure drop reduction of 21% and an increase in heat transfer coefficient of 14%. In this study, researchers found that most HVAC energy savings derived from applying UV-C occurred in fan energy (80%) followed by cooling (17%) and pump energy (3%).

According to the U.S. Energy Information Administration (EIA), in March 2022, average U.S. commercial electricity prices were up 5% over the same period in 2021. Hotter and more humid summer temperatures and higher energy costs mean facility engineers must squeeze as much cooling and dehumidification as possible from HVAC systems.

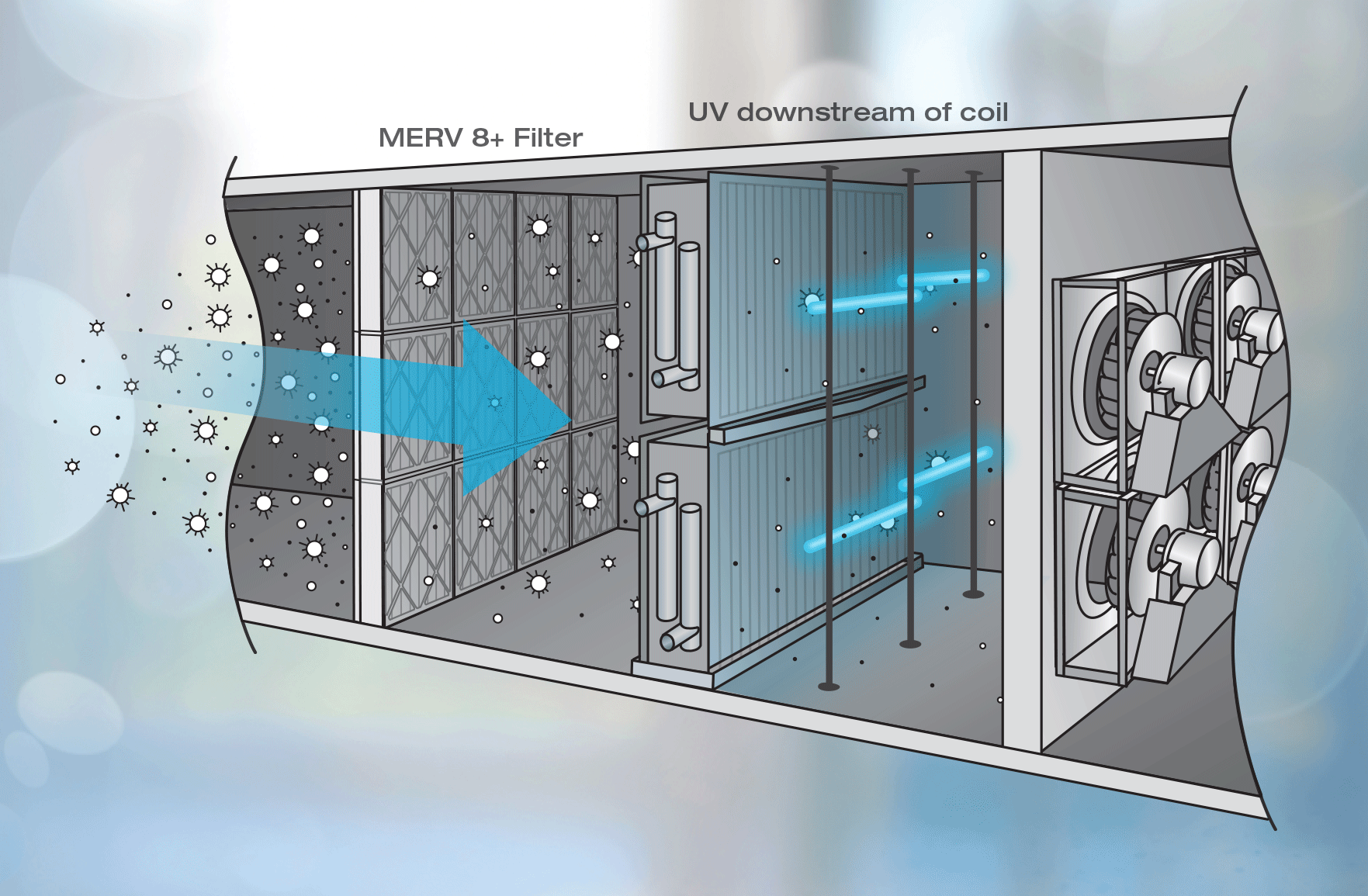

FIGURE 2: The impact UV-C has on a MERV 8 filter.

Tier 2: Improving Air Quality

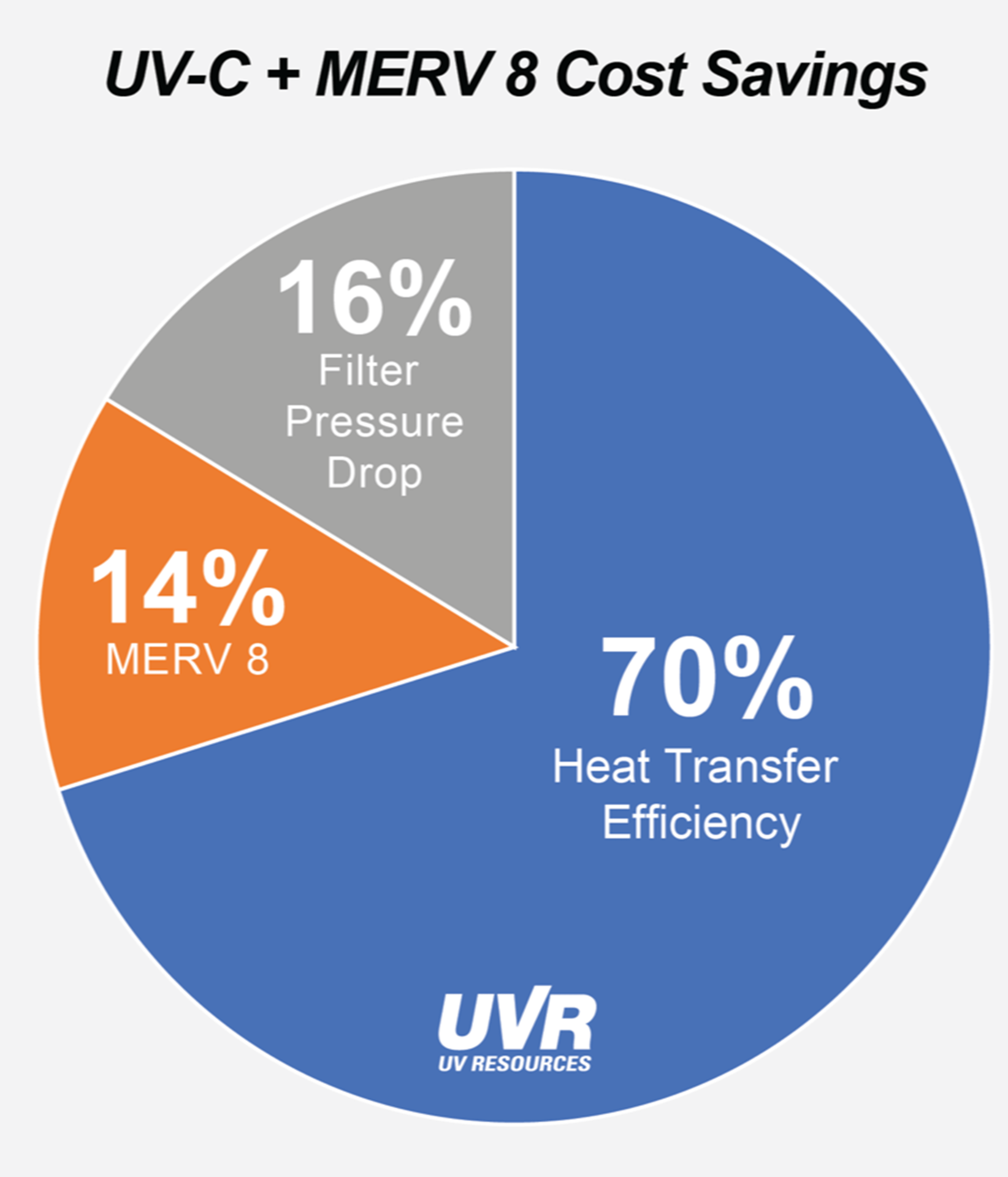

Beyond the ability of UV-C to optimize coil-heat transfer productivity and reduce HVAC energy costs by up to 20%, the second tier of savings has to do with infection mitigation strategies and the layering of air cleaning technologies.

To help prevent the airborne transmission of the SARS-CoV-2 virus, ASHRAE guidance — and, by extension, the U.S. Centers for Disease Control and Prevention (CDC) — recommend upgrading HVAC filters to at least a MERV 13 efficiency rating.

However, HVAC operators have realized that, while higher filter efficiency will reduce airborne pathogen levels, the increased static resistance stemming from MERV 13 air filters can generate unintended consequences. A higher efficiency filter, combined with the natural loading of the filter with pollutants, can decrease overall airflow levels to the point where HVAC systems are incapable of delivering the required airflow to the space.

Apart from the fact that some HVAC systems cannot drive enough air through a MERV 13 filter to meet demand, those that are capable will expend more energy to compensate for the increased resistance.

Fortunately, there is an easy-to-implement alternative for the millions of HVAC systems that were never intended to perform with MERV 13 or higher filters — and still comply with the CDC and ASHRAE Epidemic Task Force recommendations. Through a layered approach, independent research has shown that facility engineers can combine UV-C with medium-efficiency air filters, such as MERV 8, to meet or exceed MERV 13 level or higher performance efficiency rates without sacrificing airflow or compromising cooling capacity.

In addition to the energy savings that result from the lower pressure drop associated with a MERV 8 filter (e.g., less resistance, lower fan energy), building owners can significantly reduce annual filter costs. The less-restrictive MERV 8 filters cost considerably less than their MERV 13 counterparts and require fewer change-outs because they don’t load as quickly. Therefore, the more restrictive MERV 13 filters would likely need to be changed five or six times annually, while the MERV 8 filters would be changed quarterly.

Case in Point

The combining or layering of air-cleaning technologies has an exponential effect on an air-handling unit’s (AHU) overall pathogen removal performance since the MERV 8 filter captures the larger pathogens, and the UV-C inactivates the smaller, more susceptible pathogens.

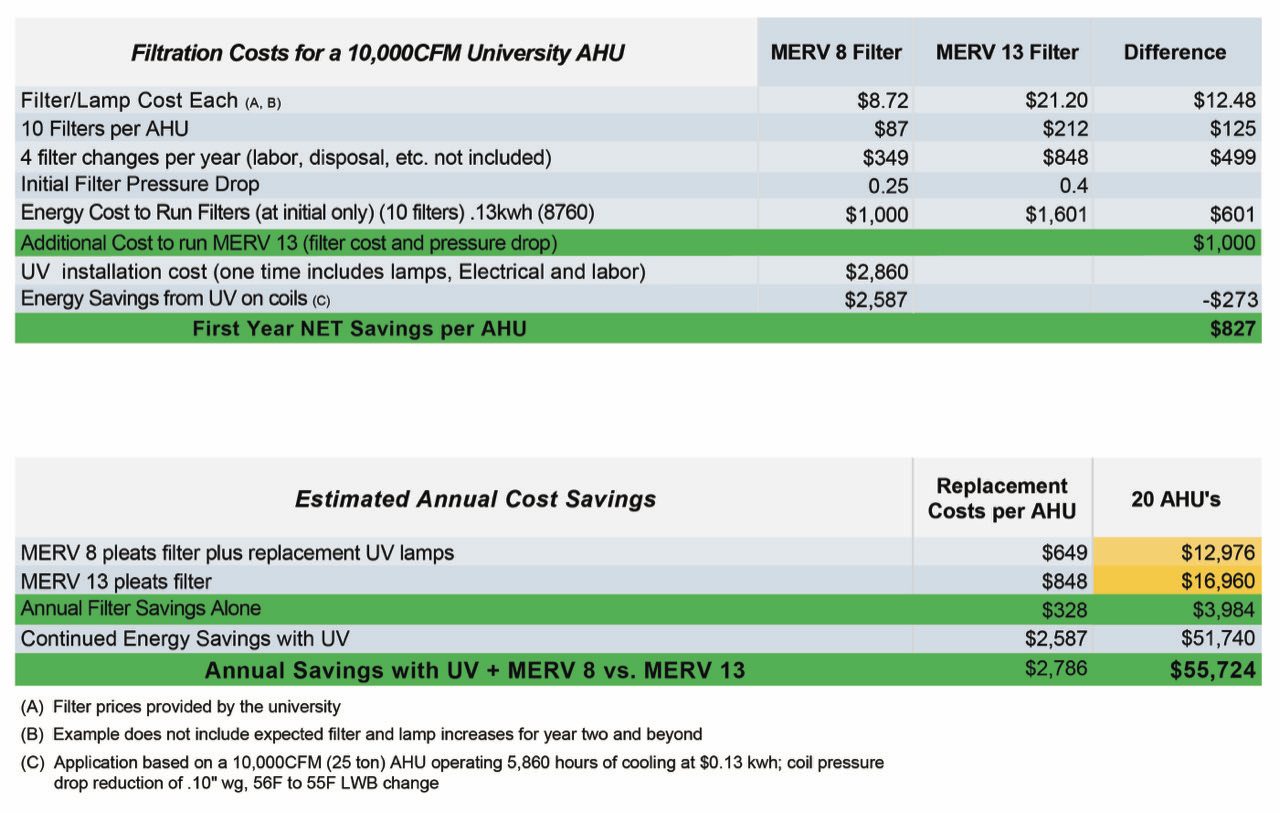

Moreover, from a budgetary perspective, as noted above, the MERV 8 filter costs roughly half its more efficient MERV 13 counterpart. As a result, it eliminates energy-intense adjustments typically used to compensate for reduced airflows, such as increasing fan speed. See Table 2 for the various categories of savings available by combing air-cleaning technologies.

A large southeastern university recently calculated the difference between utilizing MERV 13 HVAC filters alone and combining UV-C and MERV 8 filters, as shown in Table 1. For example, at one campus building served by 20 AHUs, each with 10 16-by-20-by-2-inch pleated filters that were changed quarterly, the combination of UV-C and MERV 8 saved roughly 30% in annual filter costs alone ($16,960 vs. $12,976).5 A key driver for these savings was the cost premium for the MERV 13 filters over the MERV 8 counterparts ($21.20/each versus $8.72/each).

TABLE 1. A cost analysis examining the impact of UV-C.

In the university's case, the energy savings derived from the less-restrictive MERV 8 filter (compared to a MERV 13 filter) nearly paid for the UV-C fixtures during the project’s first year ($2,587 savings toward the $2,860 installed cost of the UV system).

TABLE 2. The various categories of savings available by combing air-cleaning technologies.

With the reduced static pressure and cleaner cooling coils, university facility staff expects to spend 20% less energy using the less-restrictive filters in addition to the air filter cost savings.

With HVAC operating budgets under pressure (no pun intended), adopting UV-C can improve air quality, increase cooling capacity, and lower energy consumption. From a cost standpoint, UV-C is among the most affordable HVAC maintenance strategies. A coil efficiency system can run as little as 10-15 cents per cfm. For a 20,000 cfm system, the installed cost would be about $3,000 and provide year-round protection.

- Joseph Firrantello & William Bahnfleth (2018) Field measurement and modeling of UV-C cooling coil irradiation for heating, ventilating, and air conditioning energy use reduction (RP-1738)—Part 1: Field measurements. Science and Technology for the Built Environment. Retrieved from https://www.tandfonline.com/doi/full/10.1080/23744731.2017.1402662

- U.S. Energy Information Administration. Form EIA-861M (formerly EIA-826), Monthly Electric Power Industry Report. Average Price of Electricity to Ultimate Customers by End-Use Sector, by State, March 2022 and 2021. Retrieved from https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a

- ASHRAE. ASHRAE Technical Resources; Filtration and Disinfection FAQ. Retrieved from https://www.ashrae.org/technical-resources/ filtration-and-disinfection-faq

- Saputa, Dean, Jones, Daniel. 2022. Combining UV-C and MERV 8 Filters Exceed MERV 13 Pathogen Removal Performance. Retrieved from https://uvresources.com/uv-c-merv-8-hvac-filters-outperform-merv-13-pathogen-removal-performance/

- This figure includes the cost of the initial UV C fixture installation and replacement lamps.